July 2020

Flex-abuse

Where labor and supervision are less skilled, electrical installation quality can be very poor. However, keep in mind that all EPC contracts have codes, standards, and often owner specifications that provide overlapping requirements that mandate this be done properly and that it is verified by contractor QC personnel. But, to no avail.

One aspect seen on almost every developing country project, is the abuse of liquid-tight metal flex. Please note the photos are from NEW plants, and alarmingly in some cases not even to COD.

Flex is designed to be used in locations where there is differential movement between a piece of equipment and conduit feeding a circuit to the equipment. Flex is not intended to be a shortcut device where an electrician does not have the skill to make proper conduit bends.

Far too often, flex is used where it should not be. To put an approximate number on it, easily 50% of flex use should not exist.

In other cases, the proper fittings are not provided on each end, grounding continuity is not assured, excessive flex length is used, leaky installation is... Read more

Costs somewhat more to perform correctly.

The life-cycle ramifications for owners can be significant due to water damage of electrical and I&C devices leading to intermittent system ghost trips and failures.

Trust Us, it’s P91

At one of the world’s most spectacular power-desalination facilities, the systemic weld defect discovery resulted in a soul-crushing realization that some contractor’s self-interest has no moral boundary. If they think they can get away with something, they will certainly try, regardless of the impact to a client/owner and even themselves. Even more troubling, there really is little financial gain with some of these actions.

What started as an investigation into welding defects not properly identified in QC documentation, evolved quite dramatically when a P91 (9% Cr) hot reheat steam piping failed radially at a fabricated wye (fitting) near a steam turbine. Luckily, the failure was not catastrophic, being about 12” long, and allowed a prompt orderly unit shut down with no injury.

The fitting was cut out, and boat samples of the crack area were sent to a contractor lab and owner lab for metallurgic analysis. In the meantime, the head scratching started. It was clear early that the weld records had issues, this was visible internally. However, while waiting for metallurgy results, a... Read more

Savings from less rework and use of less skilled welders. Maybe $1mm. Cost to reweld all the large-bore in a huge power plant…??

Repair cost to the EPC contractor was immense, but the cost to the Owner was far greater due to the extended outages which persisted many years while O&M was trying to run the facility. This was well over a $100mm problem to the Owner the 1st year alone.

Weld Record Anomalies

Our default perspective is positive, and we prefer to be able to accept a story or data (documentation) as reasonably true even if we don’t believe all of it. We became gob smacked as a seemingly curious paperwork question morphed into extreme seriousness, the deeper we dug.

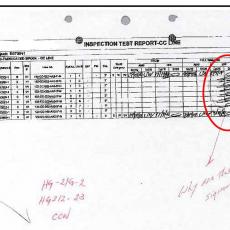

As an introduction, a review was performed of a very large facility shortly after COD. One aspect of the review was welding code compliance (ASME). This review was performed for all Section 1, BEP, and NBEP field welds for all the units/blocks. This started as a documentation review.

Initial findings were curious. Of the 25,000 large-bore field welds, only one (1) documented repair (R1) was indicated. Otherwise, the records showed no defects in any visual or radiographic inspections. Please keep in mind, the labor in this location was less than average and the work conditions extreme. In a western context, a good site welding program reject rate is perhaps 1-2%. In this situation, 4% would have been an overachievement, but 0%. This did not smell right. But all the paper appeared fine, except…

In one... Read more

Savings from less rework and use of less skilled welders. Maybe $1mm.

Repair cost to the EPC contractor was immense, but the cost to the Owner was far greater due to the extended outages which persisted many years while O&M was trying to run the facility. This was well over a $100mm problem.

RTV to Fit

EPR has been in many greenfield plants just prior, or just after COD. Basically, new plants.

Without hesitation, liquid-tight flexible metal conduit (flex) is abused and mis-installed possibly more than any other heavy industrial components, especially in developing regions.

Often labor is not given proper instruction and almost never the proper tools to install this system correctly. This results in fittings that are, at best, hand tight. Consequently, there are grounding concerns even in the best cases where flex appears to be installed correctly, assuming an internally grounded flex is used and the correct fittings. In most cases leaks occur and instead of tightening the fittings, a big smear of RTV is used as a seal. This usually does not work and creates a mess of the install.

In some plants, we have run studies in limited areas intending to be ‘representative’ and found >95% of flex fittings are loose.

For Owners concerned about the longer-term implications of moisture in electrical and instrument equipment, this is not a positive finding.

None. Probably costs more to perform incorrectly.

The cost of repair would seem manageable, but this defect is so pervasive in most plants that cost can be material. However, the O&M cost for an Owner can be even higher due to device mortality.

Spaghetti Vaults

To get a quick understanding of an EPC Contractors performance, look at a few cable vaults. Contractors that have reasonably competent labor and supervision can typically plan cable pull work and install the requisite raceway and supports in advance of their work. This is more than a nice-to-have, since it is a code requirement, and with good reason because it is intended to greatly reduce cable damage.

In a vault there are a great many details that need attending, like cable voltage separation, grounding issues, cable bend radiuses, combed/groomed/tied cables, water management, and a variety of meaningful details.

The pictures are from a couple large, NEW, greenfield plants in developing countries that were recently completed. It is possible for an Owner to monitor and insist the pictured results are avoided, but it does take engagement and follow-through.

If you see this condition start to develop on your project, it is a strong forward indicator of broad electrical quality and safety concerns. Often this condition can lead to grounding, relay, intermittent instrument faults... Read more

None.

Condition is very difficult to repair, and expensive after-the-fact because usually cable must be replaced with the coincident outages.