Safety

Spaghetti Vaults

To get a quick understanding of an EPC Contractors performance, look at a few cable vaults. Contractors that have reasonably competent labor and supervision can typically plan cable pull work and install the requisite raceway and supports in advance of their work. This is more than a nice-to-have, since it is a code requirement, and with good reason because it is intended to greatly reduce cable damage.

In a vault there are a great many details that need attending, like cable voltage separation, grounding issues, cable bend radiuses, combed/groomed/tied cables, water management, and a variety of meaningful details.

The pictures are from a couple large, NEW, greenfield plants in developing countries that were recently completed. It is possible for an Owner to monitor and insist the pictured results are avoided, but it does take engagement and follow-through.

If you see this condition start to develop on your project, it is a strong forward indicator of broad electrical quality and safety concerns. Often this condition can lead to grounding, relay, intermittent instrument faults... Read more

None.

Condition is very difficult to repair, and expensive after-the-fact because usually cable must be replaced with the coincident outages.

5kV Cable Mischief

The photos of the damaged 5,000-volt cables are from three plants that recently entered operation (at time of inspection). For every photo shown, there were dozens of similar defects.

In some instances, the cuts and holes appear to be deep enough to damage the copper shield tape. Damage to the outer jacket will allow moisture into cable jacket and cause premature failure.

The cables were seemingly not installed in a workmanlike manner and appear to have been damaged during cable pulling. This casts suspicion of the installation methods, field construction supervision, and quality control inspection processes. As a reminder, pulling cable in a raceway with sharp edges or in a manner that damages the cable is a code violation.

This type of defect does not need much explanation, but in addition to being prohibited by electrical codes, the EPC contract also had specific language related to damaged cables and accepted project methods for resolving such issues. In the absence of an Owner approved exception, there were none, the cables needed to be replaced.

In addition, the... Read more

None.

Cost of proper repair is cost of replacement. This is very high. Cost to Owner depends on how many failures related to fires, outages, or injury occur.

Trip To Work

For owners building plants, it is important to have a team that is engaging in construction oversight at the field level.

These are a few examples of a problem that we see often, which should not exist. Further, at least for electrical components (think conduit) it is a code violation to obstruct walkways and traffic areas. OSHA also addresses the issue with regulations. If this is not enough, it should be understood by most anyone, that plant workers need to be protected and nearly every power asset owner has a corporate statement of commitment to health and safety practices.

If labor is not knowledgeable enough to understand this concern in developing regions primarily (but not exclusively), then certainly contractor supervision or quality control should intervene before the work is complete.

In these photos, the plants are past COD, in a few cases over 18 months. These are also high traffic areas.

As a stopgap, O&M groups should walk the plant and add these items to an active punchlist to be sure they get resolved.

At EPR, this is an example of an item our... Read more

None, or perhaps a small savings.

Usually not large but can be left unresolved and an accident can occur. Accidents have two aspects; financial cost and a moral cost.

Tray Fill

While the subject of this post is specifically cable tray fill, the volume of defects is almost limitless in the photos. As a side note, these are new plants and, in some cases, not to COD.

To start, cable trays are usually limited to 40% of cross-sectional area as the maximum allowable cable fill. There are exceptions to this requirement, but those exceptions did not pertain to the subject plants. There are heat dissipation and overloading concerns with trays that have excess fill.

In one of the plants indicated in these photos a 5kV cable tray collapsed during final stretch of commissioning a power block which caused a 3-4 months setback to the block COD schedule. This is a real example where excess load played a factor in a materially costly event.

In addition, the photos show instances where supports are also missing according to NEMA VE-2, which compounds an overloading condition. Further, there are cables hanging over tray rails, missing and defective grounding, bent and sagging tray rungs, no voltage separation, cable transitions with no drop-out fittings, no code... Read more

Minimal cost but takes some planning and trained crews.

In many cases this condition cannot be repaired short of removing all the cables and starting over.

Rupture Disk Vent Safety

During a plant final completion punchlist walkdown, the EPR team observed a serious condition with steam rupture disk vent stack locations. The discharge point was face-high at an operator's platform.

These disks relieve pressure from a very large "reservoir" LP header at about 800F and perhaps 250psig. At some prior point, during early operations or commissioning these disks activated. The energy from this release had ripped insulation and metal jacketing from the above cold-reheat piping which was later partially repaired. However, the insulation is still imbedded in structural steel and other equipment in the area from the force of the release.

It is a serious safety concern when a standard design platform for personnel access is above the vent stack. If any personnel would have been located on the platform during this release, they would have no doubt been seriously injured or a possible fatality would have occurred.

Minimal savings...

Minimal. However, potential Owner risk is significant if a fatality occurs.

Pipe Insulation

Piping insulation installation activity unfortunately occurs when crews are under a great deal of pressure to finish. Piping is almost always at or near critical path for any industrial power project. It gets rushed.

While that explanation is a hat tip to reality, it is not an excuse for the extraordinary poor quality exhibited in many new facilities. In these photos, the plants are not more than one year into COD and look 15 years old. Over time, these plants will get worse.

For owners, quick deterioration of piping insulation can cause several problems. Heat loss, safety, and general sense by O&M staff that the plant is not worth maintaining because it certainly doesn’t look like anyone ever cared. Many overlook this point, but O&M culture affects a plant, and a plant delivered in poor condition can also work against new management trying to instill a culture of personal ownership with new crews.

So, what about heat loss. Consider technically, a few inches of open insulation on steam piping allows as much heat loss as maybe a hundred feet of properly insulated pipe (... Read more

None, or perhaps a small savings.

High, though unknowable. Suggest it’s many millions of USD. The cost of thermal drag might be as high over time.

Safety Gates

Sometimes good sense isn’t that common.

This is particularly true when it comes to safety gates at the top of access ladders. Contractors in developing regions often have a view that labor is so inexpensive, that making things is cheaper than buying items, especially if sourcing from outside the country.

Unfortunately, this ‘handmade’ product is just not of a suitable quality and the hardware provided for spring closures is equally bad. Keep in mind while viewing the photos, that companies make excellent bolt on plastic arms that last a very long time, work without fail, and are easy to install.

The importance of these items cannot be overstated and where they are absent or not working, an operator can be subjected to a nasty fall that could easily be fatal. OSHA is clear that this is not a small matter, thus the CFR 1910.23 standards that govern installation and use of such devices.

While seemingly minor, for owners that are in the process of developing specifications to attach EPC contracts, it is suggested that you pick a nice quality swing gate and allow the contractor... Read more

None. Probably cost more to fabricate a gate.

This issue is not about cost but prevention of injury and fatalities. Both can have a high financial and moral cost.

Pipe Rack Bolting

The consequence of structural failure in a power plant is operationally serious and can be life threatening.

When structures are designed for bolted connections usually "high-strength" fasteners are indicated (ASTM A325/A490). If these bolts are not installed properly, per the standard (AISC/RCSC, or other), the joint does not support the loads expected by the engineer. So, when loose bolts are observed in completed facilities, it is alarming because it is an indicator the contractor's bolting program was flawed. Properly installed bolts are verified to be pre-tensioned, which practically eliminates nuts backing off for any reason.

So what constitutes proper pre-tensioning? The code guidelines are specific, however, in simple terms bolts must achieve a certain amount of stretch. The complicating factor is that pre-tensioning varies depending on manufacturing lot, and environmental conditions like moisture because of variable thread friction. This means that daily testing (for each lot) is required to determine a "torque value" for the assembly. If this is not... Read more

Little or none.

Contractor: RCSC arbitration is moderately expensive. Owner: Risks structural failure and personnel injury.

Lightning Protection

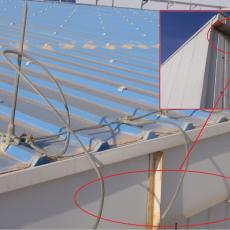

On many projects, lightning protection is installed by a subcontractor and happens near the end of a project when other activities dominate everyone’s attention.

As a system, lightning protection requires attention to details, so it is not surprising that on projects that generally suffer from workmanship problems, the lightning protection installations also suffer. This is unfortunate, because the standards are in place to provide guidance for protection from strikes that can have severe consequences to plant equipment and personnel.

For those familiar with Houston, TX, it can be easy to understand the amount of lightning present is significant. The new plants used in these examples are also in a similar flash density (flashes/mi2/yr). This is to suggest, this is important.

The EPC contract was clear in these cases regarding the requirements. The photos show workmanship defects that are representative of systematic failures throughout the systems. This included grounding conductor connections not being properly crimped and often disconnected, material incompatibility with... Read more

None.

Repairing a bad installation is not largely expensive, however, significant cost can occur for an Owner if a lightning strike occurs without a functional protection system.

Not-so Structural

Strangely, at several plants we have reviewed there seems to be at least a few occurrences of structural steel near steam turbines being gouged out by flame-cutting to fit piping or other equipment.

The reason is obvious. It takes no effort to cut a beam compared with the proper approach to ask engineering for a modification.

However, people walk and work on those platforms including often disassembling valves or other items that weigh a bit. Some of the photos show a platform that is failing (sagging) under its own weight.

Overall, not a great present for a contractor to leave an O&M team.

One high-level observation… On projects with an involved and demanding owner, the type of behavior it takes to affect these types of actions is usually not found. Why? Because it is implicitly understood there is personal risk (being fired) for an individual involved in this type of careless activity.

Minimal cost but takes some engineering involvement.

Can be a minor expense to repair, but more important as a safety issue.