Mechanical

HRSG Hot Spots

As much as this appears to be a coatings issue, it is an HRSG (heat recovery steam generator) erection problem. More specifically, a range of problems which result in hot gases coming in contact with the casing.

In the 12 units inspected at one site, all of them had visible indications of external coating damage from excessive temperatures.

Those same units were internally inspected, and the list of erection defects was extensive. Well beyond the issues that related to hot spots.

Some of the issues were missing insulation, liner damage, missing liner panels, buckled flashing, and other assembly problems.

When EPR gets involved at a site where there is visible external damage to HRSG coatings, we usually consider it an indicator of much more extensive internal problems mostly unrelated to this issue. So far, this has been accurate.

Once the HRSG problems are resolved, the hot spots can be remediated with new coatings applied using an appropriate repair procedure.

None.

Cost is mostly due to poor thermal operation of the HRSG’s.

Dirt... and Fuel Gas

As background, one critical system in a power plant is fuel gas. Typically, every system is cleaned to a condition that is nearly spotless. This is especially true of fuel gas because it feeds the turbines and duct burners. EPR evaluated a plant that was physically very large. The fuel gas header was 1.5+ miles long, inside the plant downstream of the supplier custody-filters. The system changed elevations, had countless fittings, and pipe size changes. Clearly, this is a difficult system configuration to clean well for an inexperienced crew.

Prior to EPR being involved, roughly 50 warranty claims were raised against the EPC contractor that enumerated roughly 300+ failures of valves, flame scanners, regulators, and really anything in the system with a seat or rubber O-ring. The EPC contractor refused to address the issue on-the-whole with a proper RCA (root-cause analysis), instead dealing with each item as if unrelated.

The attached photographs tell the story. This system is so full of dirt and contamination that it's not defensible to indicate proper, or perhaps any, commissioning... Read more

No Savings. Contractor went through "motions" of cleaning system, just didn't!

Just in terms of Owner down-time for needless repairs this is millions of $'s. Parts, labor, etc...

Porous Pump Castings

One aspect of power plant construction that seems to be a recurring issue is the ineffectiveness of shop inspection by some of the larger international inspection firms.

In this instance, stainless pumps were procured for seawater service. The usual shop inspection process was used, the reports sent and filed. No issues…

However, after a short period of service, there was a rash of pump failures. Keep in mind these pumps had been in service 18 months maximum.

Upon closer look, many of the pumps had casting defects that should have been caught by the manufacturer, or perhaps the supplier of the equipment that included the pumps. If not then, certainly someone on site should have inspected them, but that didn’t happen either.

Once the pumps started to fail, it was easy to see it was a fatigue failure originating from flaws in the castings.

The pictures show several different units, including one that did fail resulting in a damaged pump casing.

Things like this do happen, but they happen less if an Owner actively reviews the inspector reports and questions the... Read more

None. Should have forced supplier to deal with this issue at the factory.

None in this case because it was a Warranty item. However, these pumps are costly and from a foreign supplier. Dealing with this as an O&M group is not cheap or easy.

Pumping Rocks

At a plant in the Middle East, the EPC contractor failed to appreciate the difficulty and consequences of not properly cleaning the LP Steam distribution system and Condensate system during commissioning.

The plant was a very large combined-cycle plant with back-pressure steam turbines that fed a 72" header. That LP header in-turn fed a billion dollars in desalination equipment. This steam network was huge. Also given it's size, it would have been difficult in certain locations to get a sufficient steam velocity to remove scale and debris. It is doubtful, given the evidence of fouling in the system, that anyone tried very hard to achieve a degree of cleanliness.

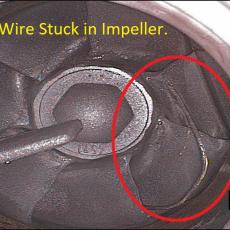

One snapshot of the damage in the system is the return condensate pump impeller indications. These impellers are supposed to have a straight (square) leading edge. Keeping in mind, these pumps were only a year old, this is not normal wear. Also, condensate is supposed to be very clean with no debris...

A borescope was used to inspect the impellers in situ during a strainer cleaning. Debris in the strainers is evident... Read more

Maybe some schedule time.

Impeller replacement. Probably $250k +/- depending on number of times. 54 units.