Pumping Rocks

At a plant in the Middle East, the EPC contractor failed to appreciate the difficulty and consequences of not properly cleaning the LP Steam distribution system and Condensate system during commissioning.

The plant was a very large combined-cycle plant with back-pressure steam turbines that fed a 72" header. That LP header in-turn fed a billion dollars in desalination equipment. This steam network was huge. Also given it's size, it would have been difficult in certain locations to get a sufficient steam velocity to remove scale and debris. It is doubtful, given the evidence of fouling in the system, that anyone tried very hard to achieve a degree of cleanliness.

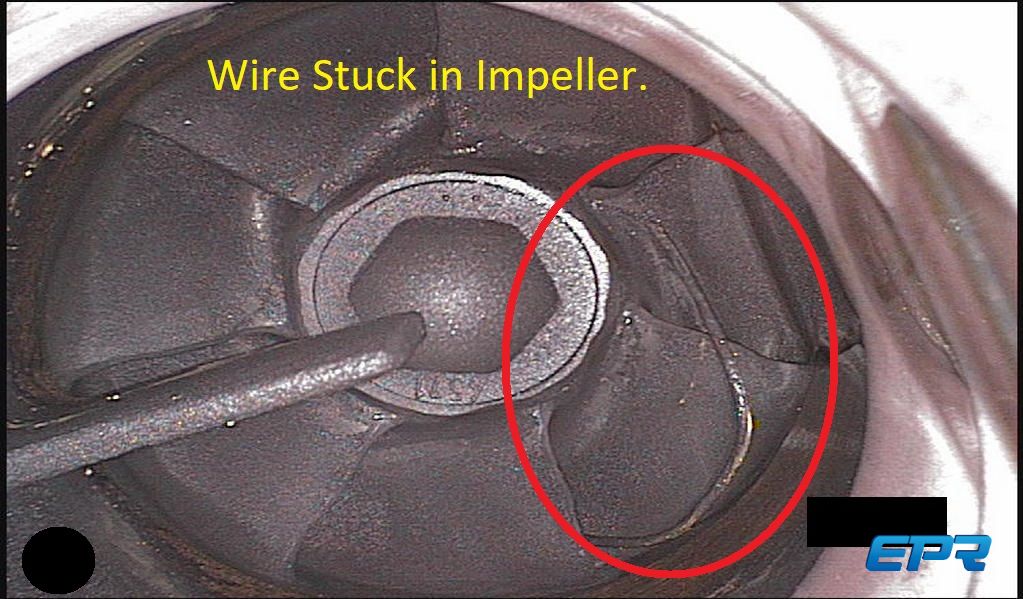

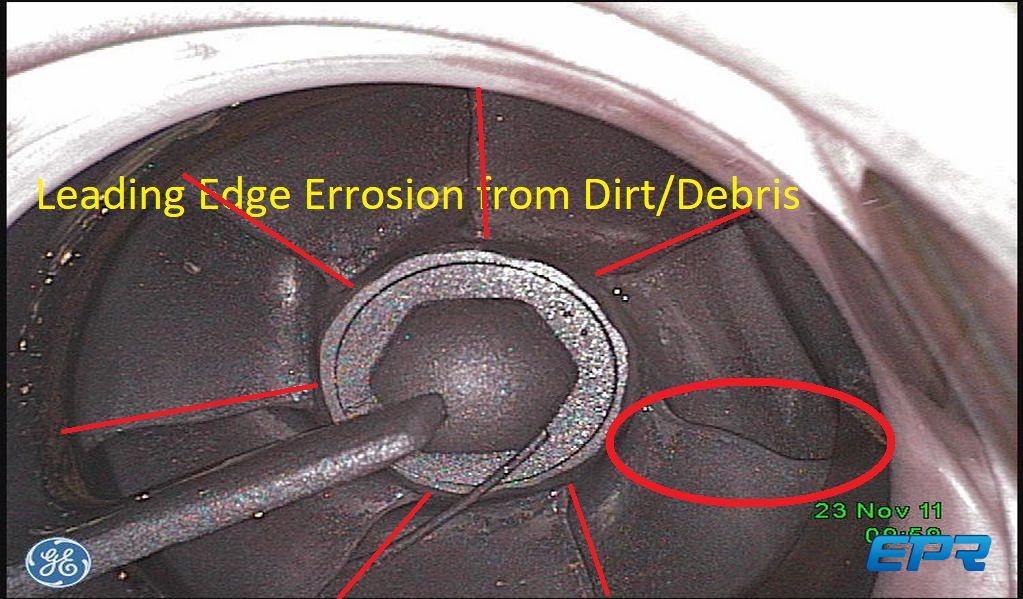

One snapshot of the damage in the system is the return condensate pump impeller indications. These impellers are supposed to have a straight (square) leading edge. Keeping in mind, these pumps were only a year old, this is not normal wear. Also, condensate is supposed to be very clean with no debris...

A borescope was used to inspect the impellers in situ during a strainer cleaning. Debris in the strainers is evident, and other problems for the keen eye. However, the leading edge of the impellers tell the full story.

Maybe some schedule time.

Impeller replacement. Probably $250k +/- depending on number of times. 54 units.