Structural Steel

Pillars of Salt & Sand (and Plastic)...

Piers are structural. This necessitates that they are installed correctly with every detail.

As with most construction defects, this is a simple problem of unskilled and unsupervised workers. The problem is compounded by a contractor culture that allows a QC program to run as a "paper" generating endeavor completely disassociated from the facts of field performance. In many cases, it's evident that there is no inspection. This is such a case...

Grout must be installed where to concrete conditions conform to the manufacturers recommendations to assure a strong bond between the materials (concrete and grout). Typically, this involves a rough surface, clear of debris, and free of any existing concrete surface coating, and similar.

Well, in this case, it's hard to imagine how these piers ended up with plastic trash being embedded at the bonding joint, among other concerns.

One certainty, there was no engaged contractor QC or owner involvement.

Essentially none...

In the future, the piers will need to be re-grouted as routine maintenance. Unknown cost.

Piers, Sort of

Sometimes people ask us how new plants end up completing so badly. EPR is not typically engaged to develop a well-studied opinion about the details of execution failure, so we tend to stay away from speculation and focus on the task of Verification of Mechanical Completion. However, we can suggest with a high degree of confidence that plants that exit construction/commissioning in poor condition are almost never resulting from engineering failures. Yes, sometimes there are oversights and errors in the plans and specifications, but it is rare enough and usually minor enough to allow us to broadly conclude execution problems are at the site.

This is one example. The drawings indicated a pier design with a spread footing to effectively keep the pier in a fixed position when loaded from pipe stress. However, the site decided to precast piers with a greatly reduced footing area, which contravened the design.

This has resulted in about 300 piers that have settled and been pushed out of plumb by piping forces. Further, the depth of cover is not suitable (<250mm) compared with the original... Read more

Some, but relatively minor. ~$25,000.

The cost of replacement is small compared to the damage to rotating equipment and other components.

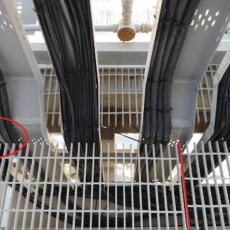

Pipe Rack Bolting

The consequence of structural failure in a power plant is operationally serious and can be life threatening.

When structures are designed for bolted connections usually "high-strength" fasteners are indicated (ASTM A325/A490). If these bolts are not installed properly, per the standard (AISC/RCSC, or other), the joint does not support the loads expected by the engineer. So, when loose bolts are observed in completed facilities, it is alarming because it is an indicator the contractor's bolting program was flawed. Properly installed bolts are verified to be pre-tensioned, which practically eliminates nuts backing off for any reason.

So what constitutes proper pre-tensioning? The code guidelines are specific, however, in simple terms bolts must achieve a certain amount of stretch. The complicating factor is that pre-tensioning varies depending on manufacturing lot, and environmental conditions like moisture because of variable thread friction. This means that daily testing (for each lot) is required to determine a "torque value" for the assembly. If this is not... Read more

Little or none.

Contractor: RCSC arbitration is moderately expensive. Owner: Risks structural failure and personnel injury.

Not-so Structural

Strangely, at several plants we have reviewed there seems to be at least a few occurrences of structural steel near steam turbines being gouged out by flame-cutting to fit piping or other equipment.

The reason is obvious. It takes no effort to cut a beam compared with the proper approach to ask engineering for a modification.

However, people walk and work on those platforms including often disassembling valves or other items that weigh a bit. Some of the photos show a platform that is failing (sagging) under its own weight.

Overall, not a great present for a contractor to leave an O&M team.

One high-level observation… On projects with an involved and demanding owner, the type of behavior it takes to affect these types of actions is usually not found. Why? Because it is implicitly understood there is personal risk (being fired) for an individual involved in this type of careless activity.

Minimal cost but takes some engineering involvement.

Can be a minor expense to repair, but more important as a safety issue.

Coatings Delamination

EPC Contract indicated “the project site is subjected to moist and heavily polluted salt laden air”…

While the contractor took precautions to properly specify the coating systems, the surface prep and coatings application was flawed anyway. Normally, an effective shop (or field) inspection program will catch the problem early and be resolved in favor an effective coating process. In this facility, there was extensive evidence that either no QC program existed, or the inspector(s) were compromised.

After 18 months in operation, the coatings appear 15 years old. To varying degrees, most of the structural steel coating systems in the subject plant are in a progressive state of failure with the substrates rapidly and increasingly unprotected.

It was determined much of the steel coatings suffer from varying failure mechanisms. However, this photo is an example of improper surface prep (NACE/SSPC) and inconsistent dry film thickness, often with a top-coat greatly exceeding manufacturers requirements.

Minimal to no cost savings. Some time may have been saved if rework in the shops had been required.

Owner: Coating system will need an aggressive repair program as opposed to the anticipated touch-ups. Magnitude large but unknown.

General Welding

In a completed facility inspected by EPR, there was a noticeable level of unacceptable general welding. As a frame of reference, this plant was purchased to be built by an experienced contractor to western standards (AWS) in a location where suitable labor was available.

During the initial stages of the review, it became clear that some workmanship lapses were so pervasive that a plant-wide cataloging of the defects was impractical. Therefore, a detailed review was conducted on one power train to determine a representative condition of the whole plant related to general welding.

171 welds on pipe supports, electrical cable tray/conduit supports, and gallery steel were evaluated per the visual acceptance criteria standards of AWS D1.1, Sections 5 and 6. 20 (twenty) were found to meet the most basic “stand-back” visual acceptance criteria of the AWS D1.1. Effectively, at least 89% of the welds did not meet the AWS visual acceptance criteria, and many (most) failed with multiple defects. Keep in mind this investigation did not get into real detail with the use of Cambridge or fillet... Read more

Clearly some money was saved, but it could not have been significant.

Owner: Could be as little as occasional maintenance labor for failed items, or significant when important failures occur costing operating hours/days.

HRSG Bolting

Large (HRSG) equipment erection is about attention to detail, but not overly complex. However, the structural and thermally cyclical nature of these units demands that proper methods and OEM instructions be observed.

In this case, a large new plant with 12 units was inspected one year after COD by EPR. There were so many deficiencies it is clear proper procedures were not followed. For high-strength bolting (ASTM A325/A490) proper pre-tension testing must occur, in addition to proper substrate alignment, thread engagement, and other details. The pertinent requirements, in addition to being code stipulated, were cascaded with clarity in the Contractor’s own specs and procedures, so they should have been followed and QC verified.

For both slip-critical and direct-tension applications bolting was observed to be missing, loose, installed in flame-cut holes, loose plies, and a variety of concerning problems. Over time, this condition will worsen and result in two safety concerns; falling fasteners, and unsafe structures.

Minimal. It takes no more time to pretention bolting by the iron worker. Further, QC checks should have been performed.

Owner: Safety and outage concern. Repairs need to be affected. EPCC: ~$25,000 per unit for equipment, new bolting, and man-lifts.

Not-So-Structural Grating

After noticing an unusual number of severe workmanship issues with grating penetrations, a study was conducted on one portion of a recently visited facility (one power block).

In the subject area, 231 penetrations through grating or deck plate did not conform to the requirements of contractor’s own Structural Erection Procedure, which states that all cuts of 3 grating bearing-bars shall be banded, and further, that field-cut openings shall clear insulation by 1”. The contractor’s own structural drawings also indicate a requirement/detail showing the penetrations of grating and checker plate reinforced with toe plate and banding.

Of the 231 inspections, 39 were missing banding, 174 had no toe plate, 10 did not meet the required insulation clearance, and 8 open holes were left in the grating. In total, roughly 100% of the penetrations were out of compliance with normal practice and the contractor’s criteria indicated above.

More concerning, is that the workmanship is so poor in some instances that almost none of the bearing-bars remain intact leaving the structural integrity of the... Read more

Labor/Supervision savings and probably some material.

Contractor: Some material expense and labor. Scaffold in some locations perhaps. Owner: Risks injuring O&M personnel or worse.

Weld Slugs

Proper power plant construction is typically based on layers of processes and checks. Often observed quality problems are concerning due to their possible systematic nature and origin as a supervision problem.

In the realm of field welding, few defects speak as clearly about poor contractor quality and a loss of accountability than a slugged weld. The attached photo reveals that a piece of “all-thread” rod was used to fill several weld passes. Even worse, the welder didn’t even feel compelled to bury the slug under the cap and so it remained exposed. This indicates a site ethic existed, where the welder felt there was no consequence to being caught, or perhaps the welder was confident that no one would verify his work.

There may be several codes or standards that cover this type of activity, but it violates the general welding standards of AWS. The practical reason “slugs” are not acceptable is due to the uncontrolled and usually low-grade nature of the material used as “slugs”. This implies a possible structural deficiency, which is of course not acceptable.

In this facility,... Read more

The joints need welding, to do it wrong saves no time. Unqualified labor may be marginally cheaper, but not if the work is rejected!

Contractor: Cost of repair is small; but brand damage is meaningful. Owner: Structural failure risk increases, but small. Concerning indicator of plant quality!

No-No-Shrink Grout

Most structural designers call for an inch or two of no-shrink grout below the baseplates of structural columns. While anchor bolts are installed with nuts to jack and plumb a column, the load is intended to be carried largely by the grout. This means that it needs to be installed on a prepared surface, mixed correctly, and placed with good workmanship to the approximate depth required.

In almost every developing country where EPR has inspected plants, the same recurring problems are visible. Typically, the workman are unaware of the purpose for the grout and methods required to create an acceptable final product.

In the photos, at least three major flaws are shown. First, the foundation surface was not bushed prior to setting the column and instead some half-effort to rough around the joint is attempted. Second, there is insufficient space to apply grout below the baseplate. Third, the grout is poured around the joint, as opposed to being packed under the baseplate. It is clear the workman think grout is simply a "dressing" rather than a purposeful component of the structural system.

... Read moreNo Savings.

Most of the time, the condition is not repairable. Owner had to accept the defect.