RTV to Fit

EPR has been in many greenfield plants just prior, or just after COD. Basically, new plants.

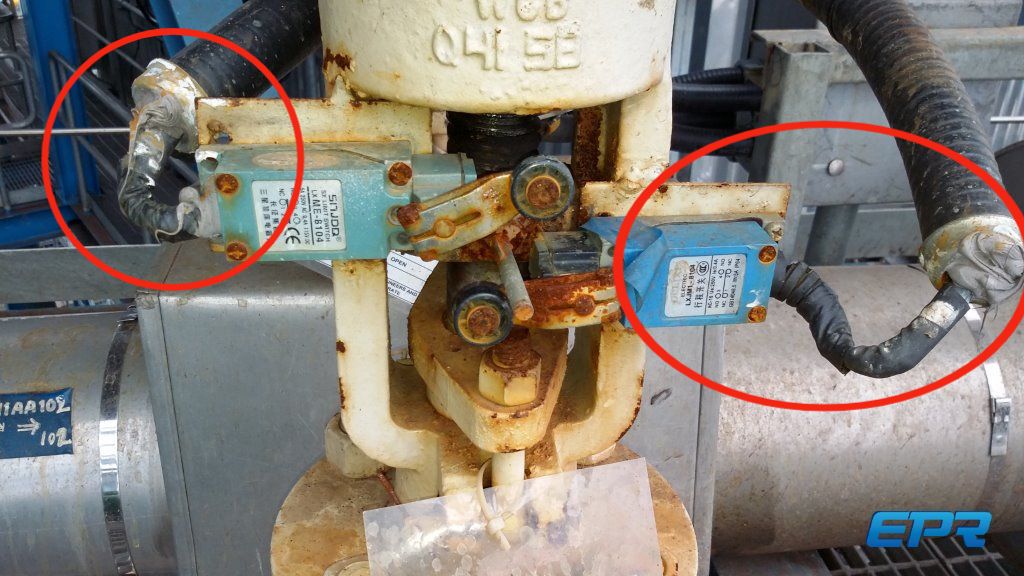

Without hesitation, liquid-tight flexible metal conduit (flex) is abused and mis-installed possibly more than any other heavy industrial components, especially in developing regions.

Often labor is not given proper instruction and almost never the proper tools to install this system correctly. This results in fittings that are, at best, hand tight. Consequently, there are grounding concerns even in the best cases where flex appears to be installed correctly, assuming an internally grounded flex is used and the correct fittings. In most cases leaks occur and instead of tightening the fittings, a big smear of RTV is used as a seal. This usually does not work and creates a mess of the install.

In some plants, we have run studies in limited areas intending to be ‘representative’ and found >95% of flex fittings are loose.

For Owners concerned about the longer-term implications of moisture in electrical and instrument equipment, this is not a positive finding.

None. Probably costs more to perform incorrectly.

The cost of repair would seem manageable, but this defect is so pervasive in most plants that cost can be material. However, the O&M cost for an Owner can be even higher due to device mortality.