HRSG Bolting

Large (HRSG) equipment erection is about attention to detail, but not overly complex. However, the structural and thermally cyclical nature of these units demands that proper methods and OEM instructions be observed.

In this case, a large new plant with 12 units was inspected one year after COD by EPR. There were so many deficiencies it is clear proper procedures were not followed. For high-strength bolting (ASTM A325/A490) proper pre-tension testing must occur, in addition to proper substrate alignment, thread engagement, and other details. The pertinent requirements, in addition to being code stipulated, were cascaded with clarity in the Contractor’s own specs and procedures, so they should have been followed and QC verified.

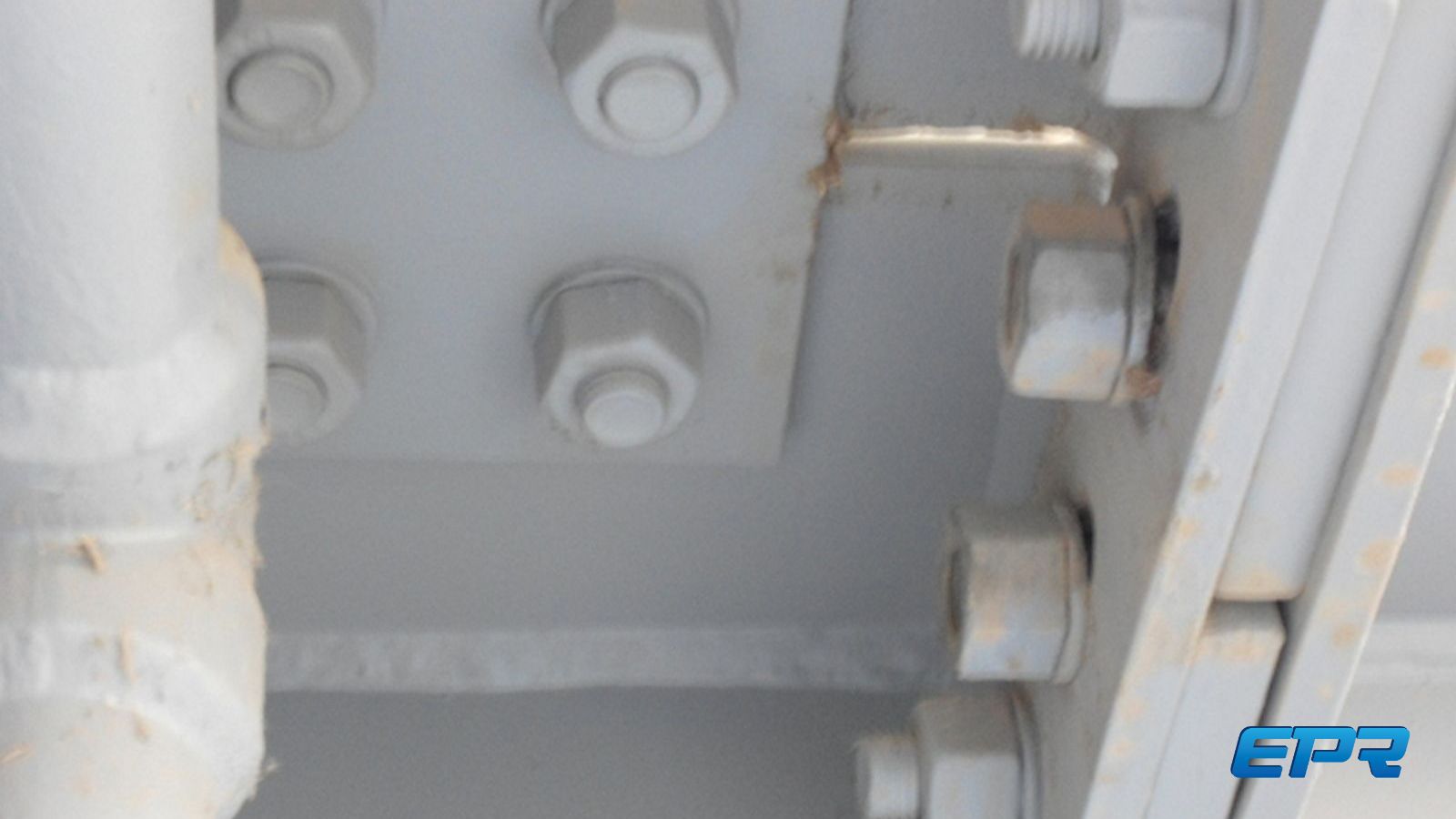

For both slip-critical and direct-tension applications bolting was observed to be missing, loose, installed in flame-cut holes, loose plies, and a variety of concerning problems. Over time, this condition will worsen and result in two safety concerns; falling fasteners, and unsafe structures.

Minimal. It takes no more time to pretention bolting by the iron worker. Further, QC checks should have been performed.

Owner: Safety and outage concern. Repairs need to be affected. EPCC: ~$25,000 per unit for equipment, new bolting, and man-lifts.