Galvanized Hardware (Or Not)

When a plant is built in a moist, heavily polluted, and/or salt laden environment, corrosion protection is a serious consideration. At a minimum, hot dipped galvanized hardware (nuts, bolts, washers, clips, etc.) is usually specified for outdoor service.

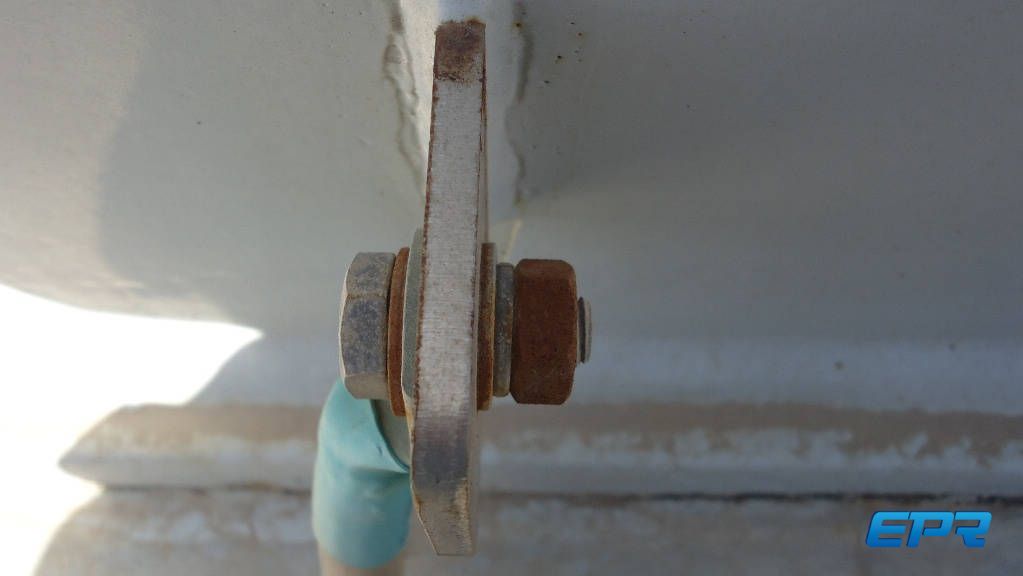

In a recently visited new facility, aggressive corrosion was exhibited almost universally on the hardware. What was discovered is that wherever galvanized was specified, electro-galvanized, electroplated zinc, or zinc plated, (different terms, same thing) was substituted by the contractor. This results in a 3 to 12 micron coating that gives it a much lower degree of corrosion protection than hot dipped galvanized with an 85 to 90 micron layer of zinc. IEC indicates these coatings degrade (in this environment) at 4-8 microns/year. It's then easy to see why there is so much aggressive corrosion and advancing stages of metal loss after only a couple years.

In the rare cases where hot dipped galvanized was provided, it seemed to perform well.

Marginal material cost savings; No labor savings.

Contractor: Substantial cost (Labor/Material) to replace fasteners in bulk. Owner: Fasteners failing is significant. Electrical system risks increase over time.

Cable Tray Hardware

After only a couple years, tray splice hardware is failing. The structural properties of the tray system has to be in question in perhaps another few years.