Tickle Me Raw

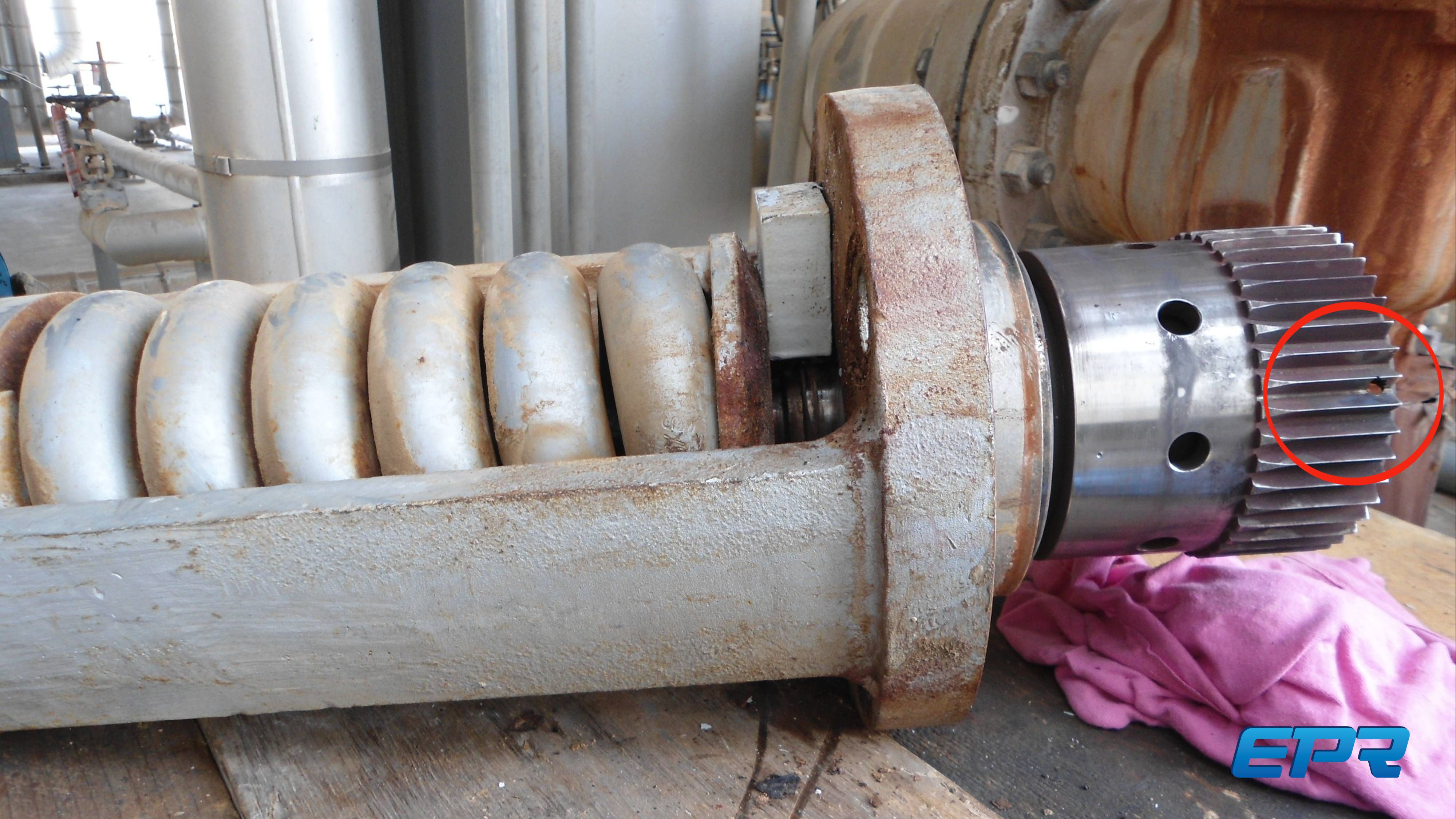

A new greenfield plant was reviewed by EPR, 12 months post COD. The problems related to improper commissioning were extensive and will shorten the life cycle of all the major equipment, some of which was already apparent this early in operation.

One problem that seemed to vex the O&M staff was continual failures of some safety valves.

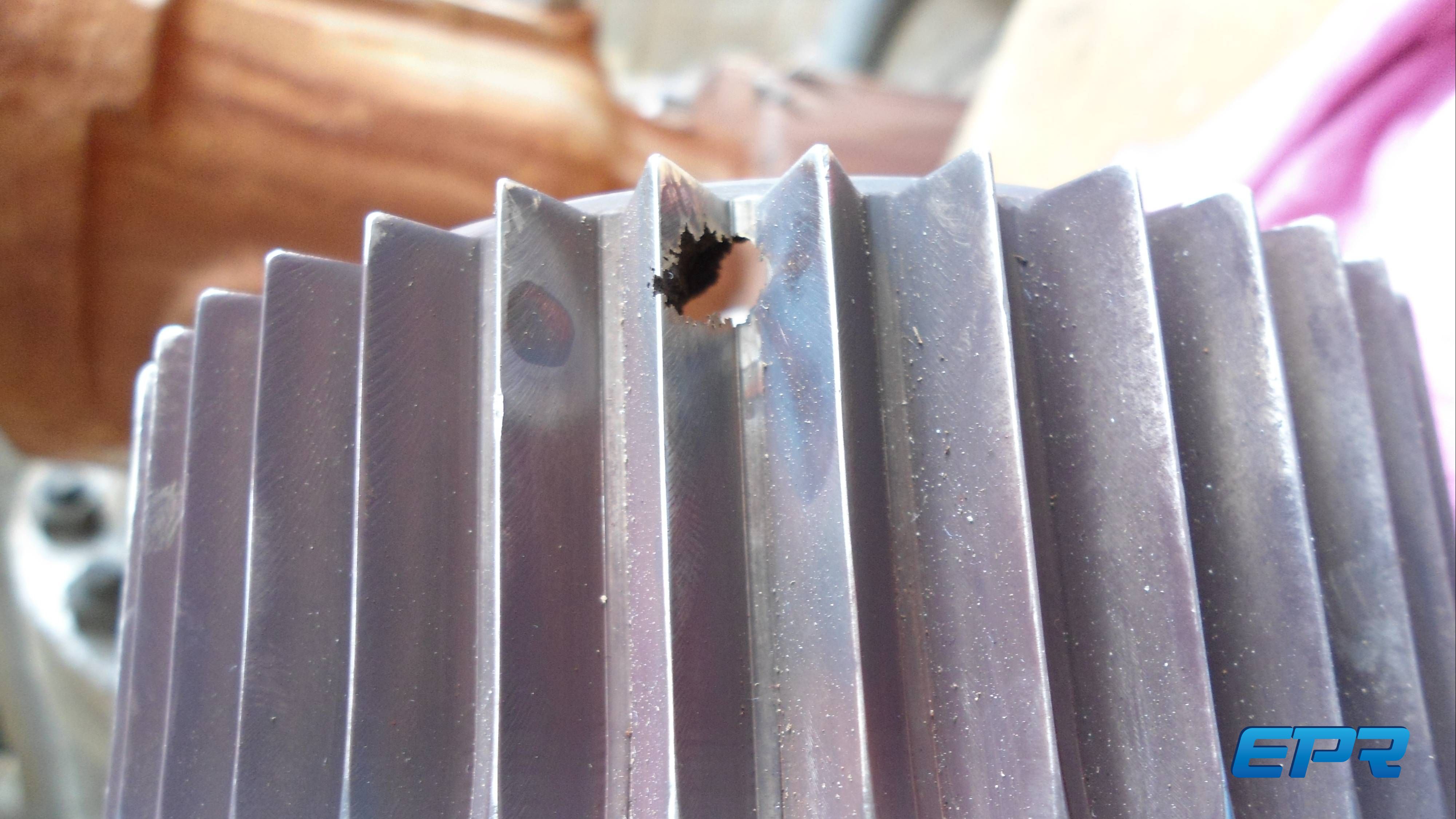

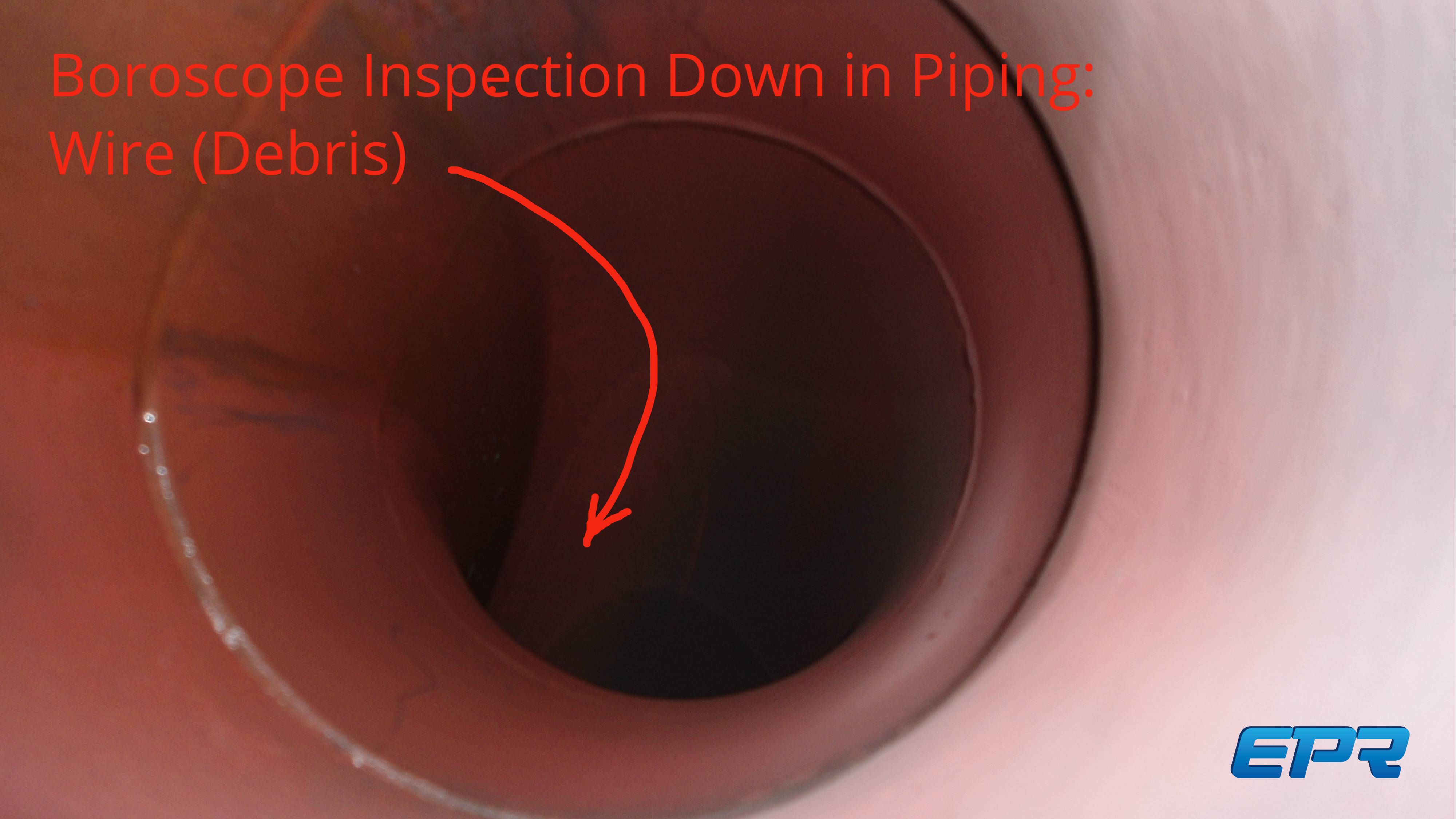

What was eventually discovered by EPR with the aid of a borescope was debris in the piping that upon disassembly would fall far enough back inside to be difficult to see. During operation, this debris would rub against the safety valve disks and erode a hole.

The objective of commissioning piping systems is to be certain, with verification, that no debris, mill-scale, or other contamination remains that can damage components. In this instance, the foreign matter was wire that was not flushed or blown out during cleaning.

The records created by commissioning for this system indicated all the proper steps and procedures were followed and verified. However, the reality was clearly different, and it was easy to conclude with certainty this system was either cleaned in a cursory manner, or perhaps not at all.

This problem occurred at many of the safeties during the period EPR was on the site causing considerable cost and additional outage activity for the Owner.

No cost, but perhaps a day or two of schedule.

Unknown. Replacement disks will need to be stocked and replaced until the systems can be cleaned up.