"Old School" Steam Drains

Keep in mind, this is a new plant in operation about one year, in a location where quality plants are built routinely... Yes, this is a NEW plant built to contemporary codes and standards by a large international EPC contractor.

During EPR's review of the Facility, this system is perhaps the single most compelling example of inferior design in the plant. While not the most cost intensive, the effects are broad reaching. The open trench design belches hot condensate on steel, electrical hardware, and other equipment leaving the plant to look ready for decommissioning. O&M personnel are left to perhaps unknowingly assume that facility condition is not important to the owners; how could it be, look at this? In so many ways this is not consistent with the Facility purchased.

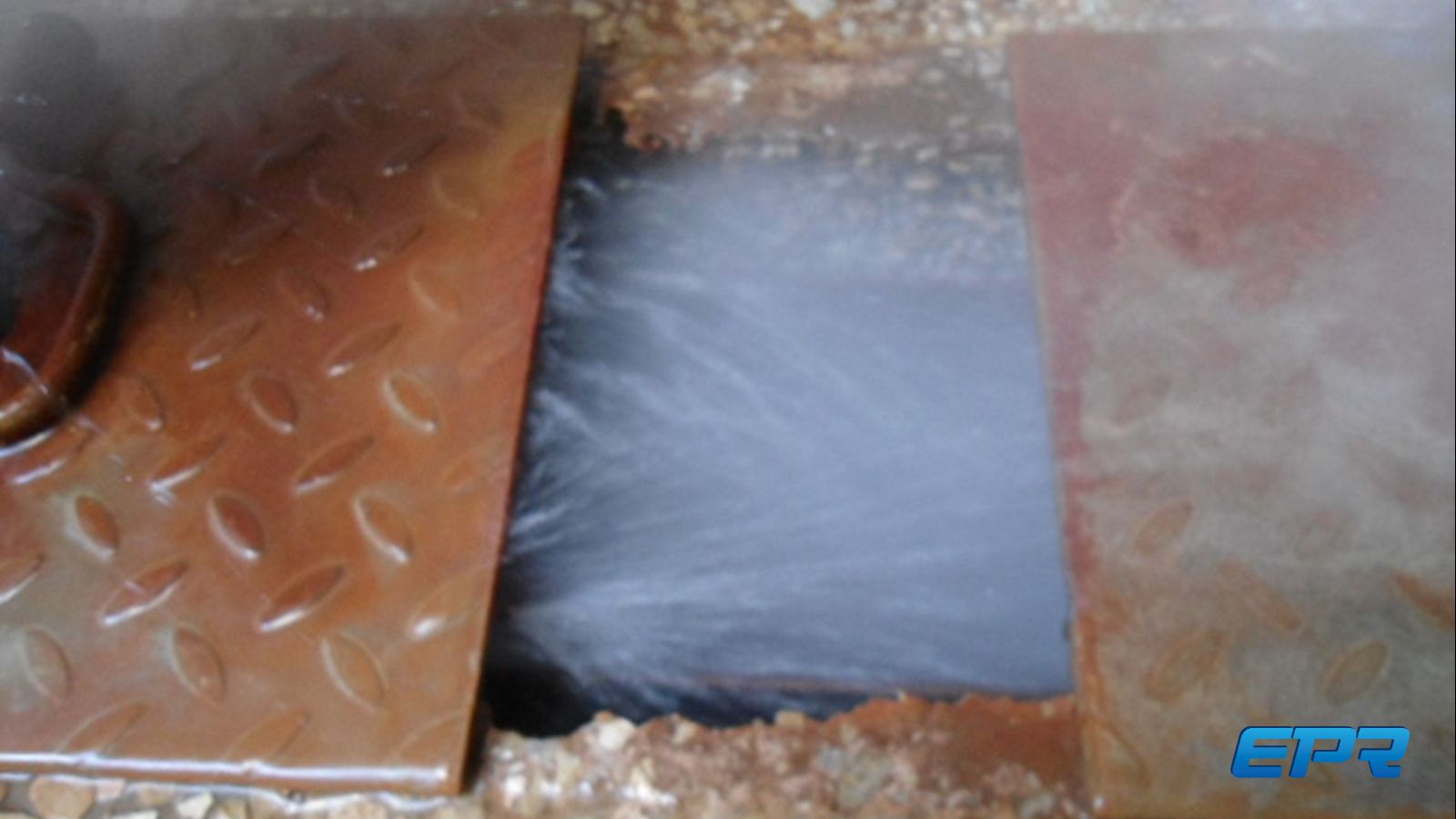

The condensate collection system of trenches and transfer sumps has experienced critical deterioration. Serious failures in the concrete infrastructure include trench through-cracks, cementitious erosion, advanced concrete spalling and scaling, sub-grade undermining, differential settlement, and accelerated corrosion of adjacent electrical and mechanical equipment. The amount of degradation to these utilities invokes serious concerns to their structural integrity under continued operations.

The open trench arrangements are inefficient in isolating and dissipating the blowdown energy and containing the condensate from the local high-energy piping systems. As a result, significant damage has occurred to the trench concrete containments. Likewise, flash steam from open-ended drain piping discharging into these trenches result in elevated temperature and humidity levels conducive to corrosion cell development in local structural steel, mechanical equipment, and electrical conduit and boxes.

The attached photos represent a small percentage of failure mechanisms and equipment deterioration noted by the EPR inspection team. Steel liner plates are installed in several trenches, where other similar units are unlined. Blowdown and drain piping are hard-piped and welded to in-trench headers within the trench containment for several HRSG installations but are open-ended and uncontained for other similar unit facilities. In these areas, the accelerated corrosion to local electric panels, conduit chases, control valves, and ancillary piping significantly impacts the integrity and life expectancy of critical equipment.

A modern power plant always uses piped drains systems. There are operating and serious environmental reasons for avoiding such a design.

Perhaps $500k.

Unknowable, but very significant. Violates Environmental permit, among other problems.