Inspection Futility

Often field quality suffers from a lack of oversight, quality control, supervision, or owner involvement. Sometimes a contractor and owner set out to assure their interests are protected, but it fails anyway.

Using a large international source inspection firm tends to be where problems arise. Those firms use local inspectors to keep costs down by limiting travel. However, local inspectors are often the same people that visit particular shops and due to familiarity, a relationship develops which compromises the effectiveness of the shop inspection. Instances exist in remote areas where inspectors are relatives of shop owners. The main take-away, is that inspections by ineffective, conflicted, or technically limited personnel with no personal connection to your project is wrought with peril.

The opinion of the author is that if an inspection is worth performing by an owner, send your own people, or an inspector well known and hired directly. It will be more cost than outsourcing with a large international inspection firm, but it will be worth it.

At one facility, the contractor and owner agreed to send a third-party inspector hired through one of the aforementioned firms. The subject shop was a Chinese pipe fabrication firm that was to spool and coat roughly 30Km of piping. The shop reports indicated everything was found acceptable.

When the piping arrived at the receiving port, EPR was asked to go look.

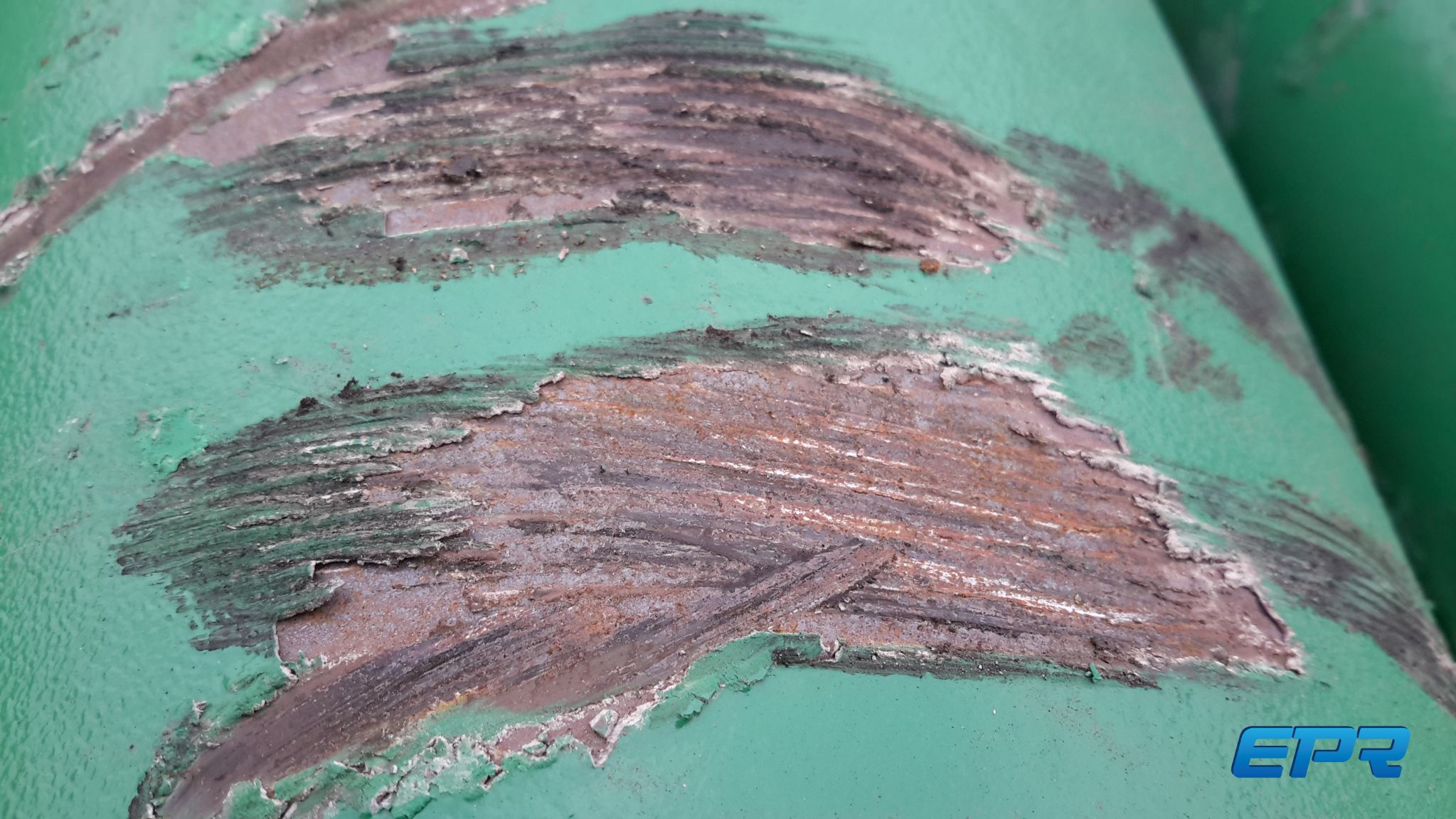

The piping coatings were abused during loading and offloading and improperly packaged for safe shipment. However, the more serious discovery related to the condition of the pipe coatings.

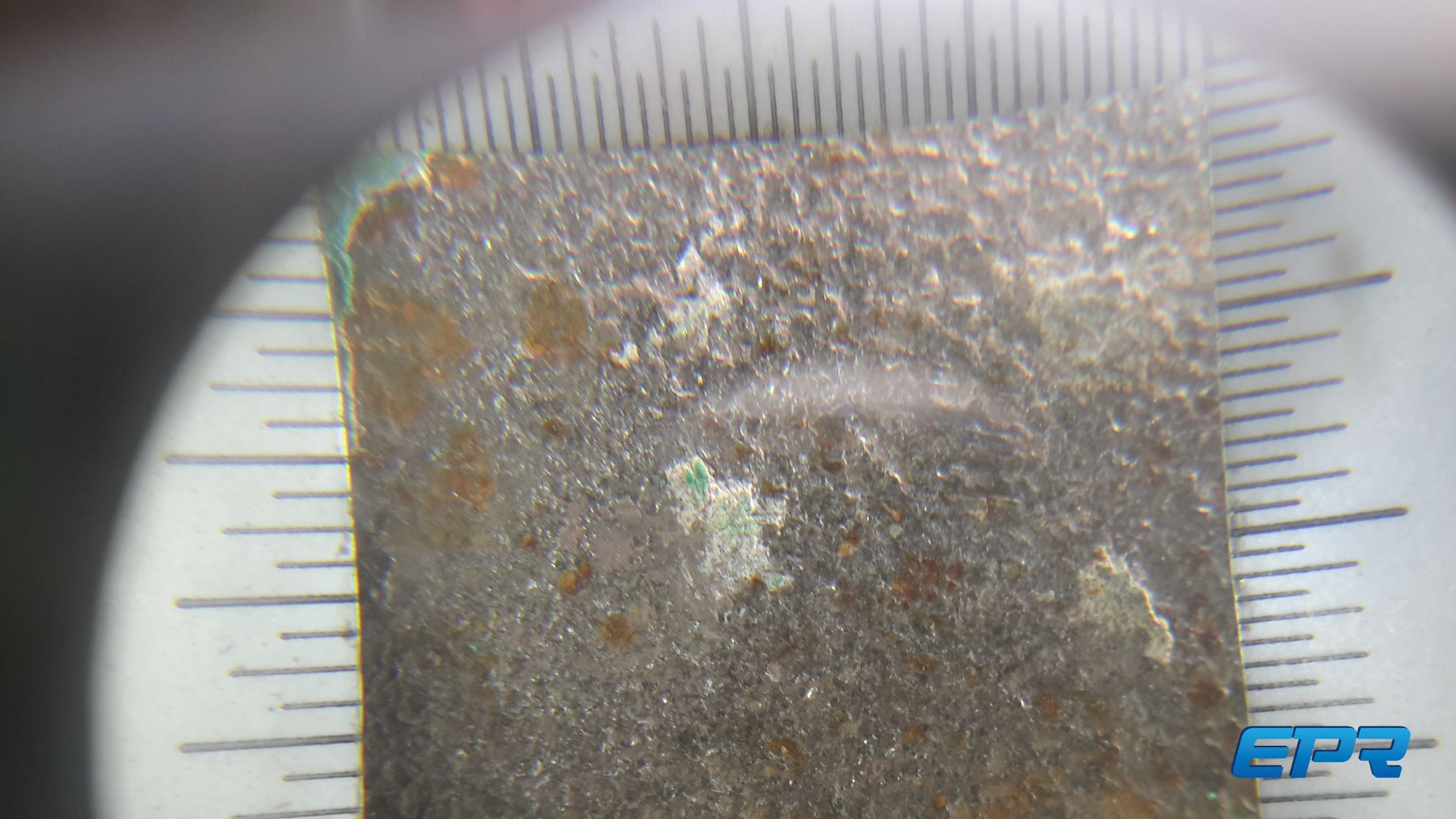

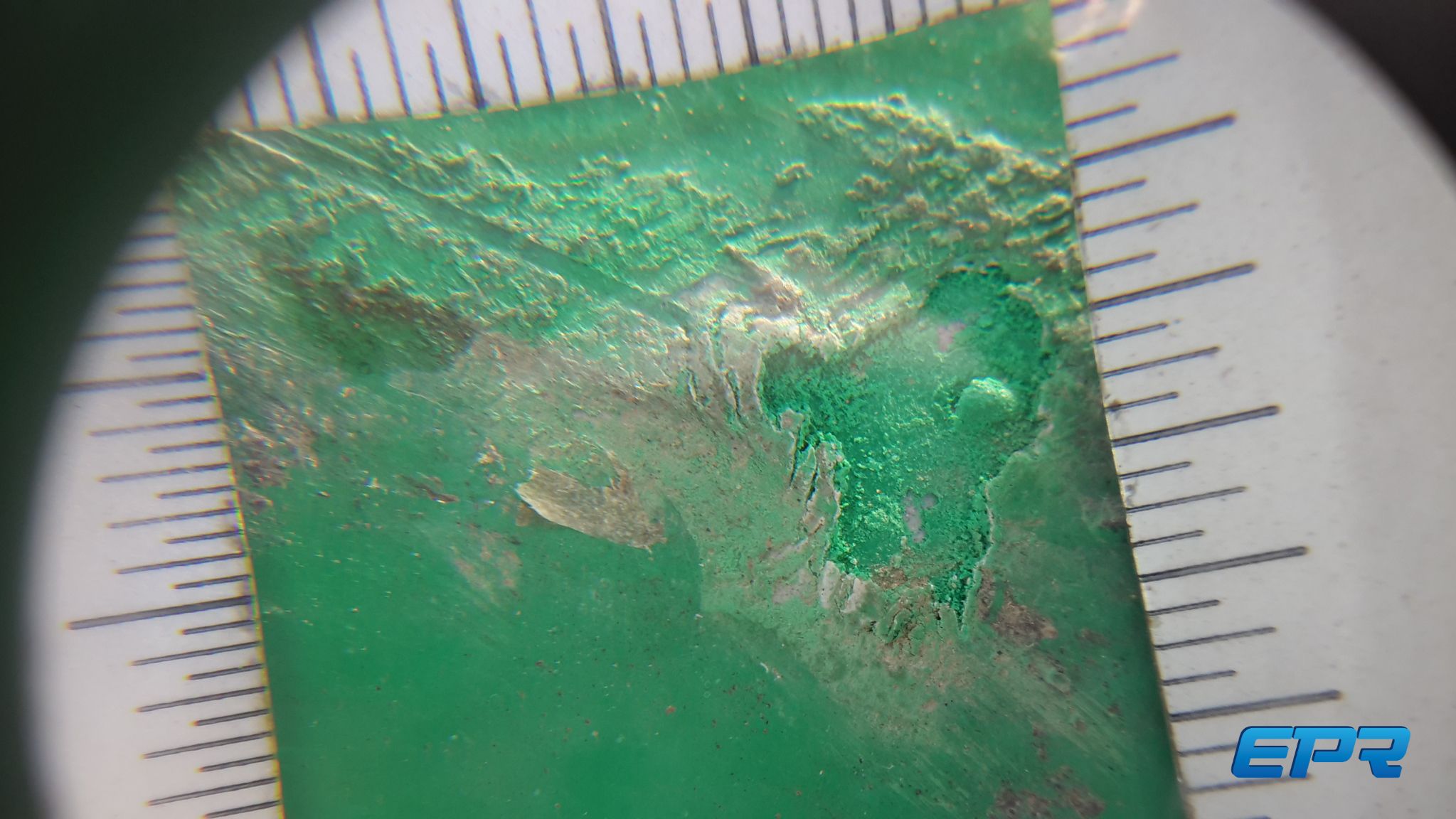

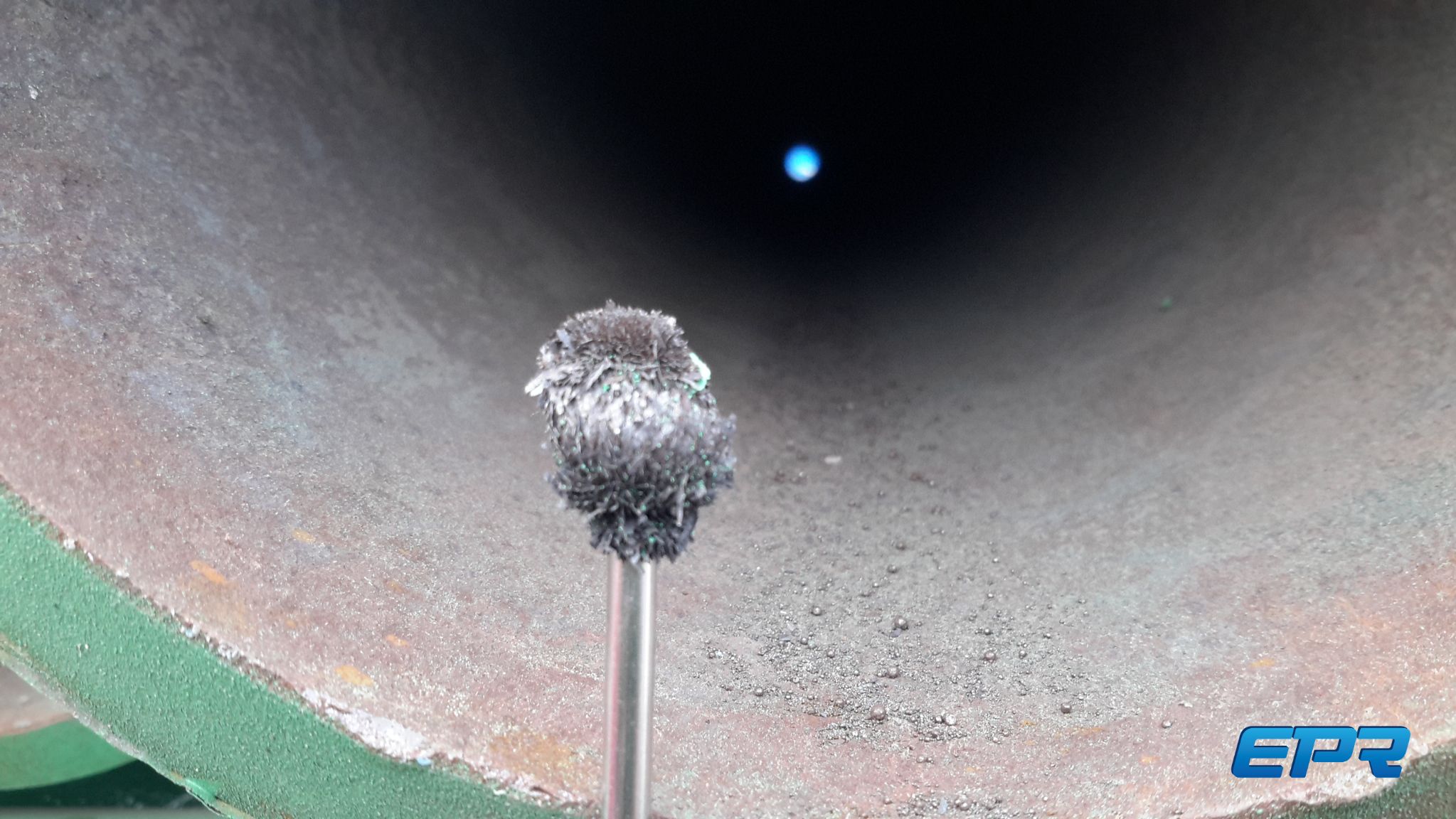

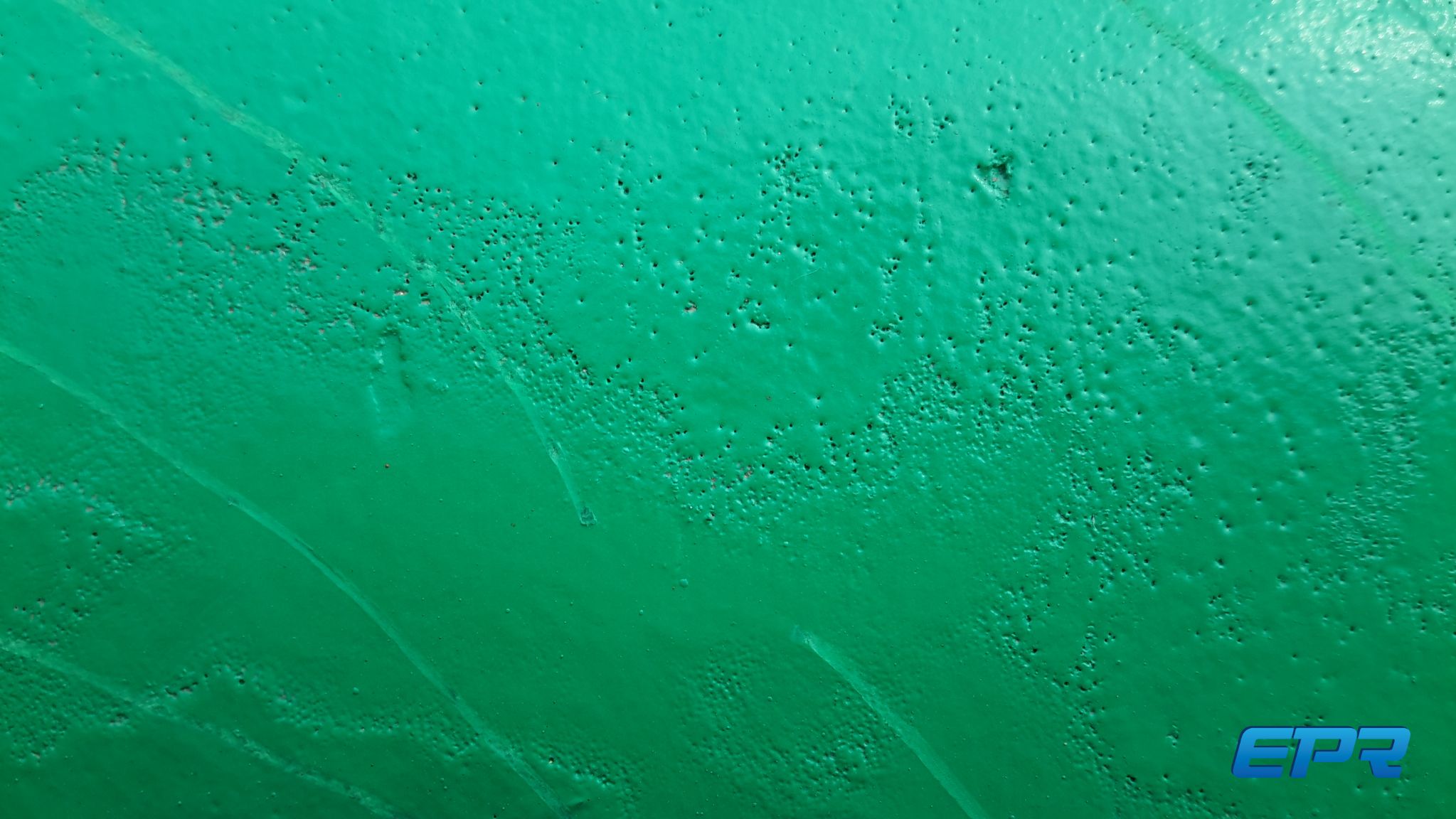

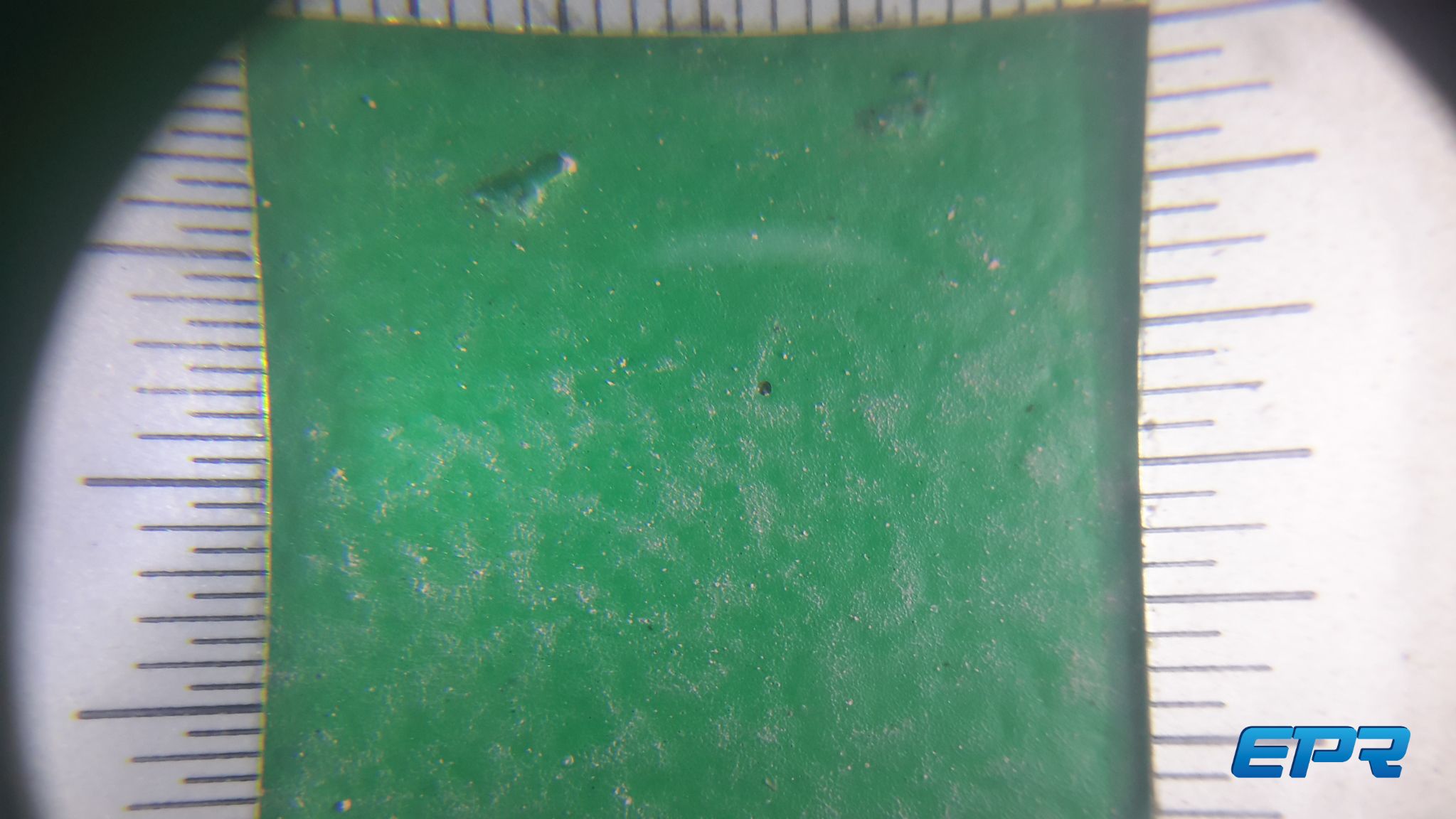

Essentially every NACE/SSPC coating practice/requirement and the manufacturers guidelines were ignored. The coatings were uncured due to improper catalyst mixing. The pipe surface was blasted with steel shot, but not completely. The steel contamination from the steel shot was not cleaned off the piping, leaving contamination for future corrosion. Blasting was performed near or adjacent to painting operations causing steel shot to be impinged in the wet coatings and between coatings layers. The coatings had other problems (could have been several causes) which resulted in pinholes in the coating systems.

Any one of these defect mechanisms is enough to reject the whole lot. Further, all of these problems are very easy to spot by any inspector dedicated to his work.

So, despite the contractor's effort to assure the shipment was of specified quality, it was not even close. All because some inexpensive third-party shop inspector was incompetent or somehow conflicted. All coatings had to be removed and replaced at great expense and wasted time.

None.

$150k +/- and wasted time.