Getting Touchy

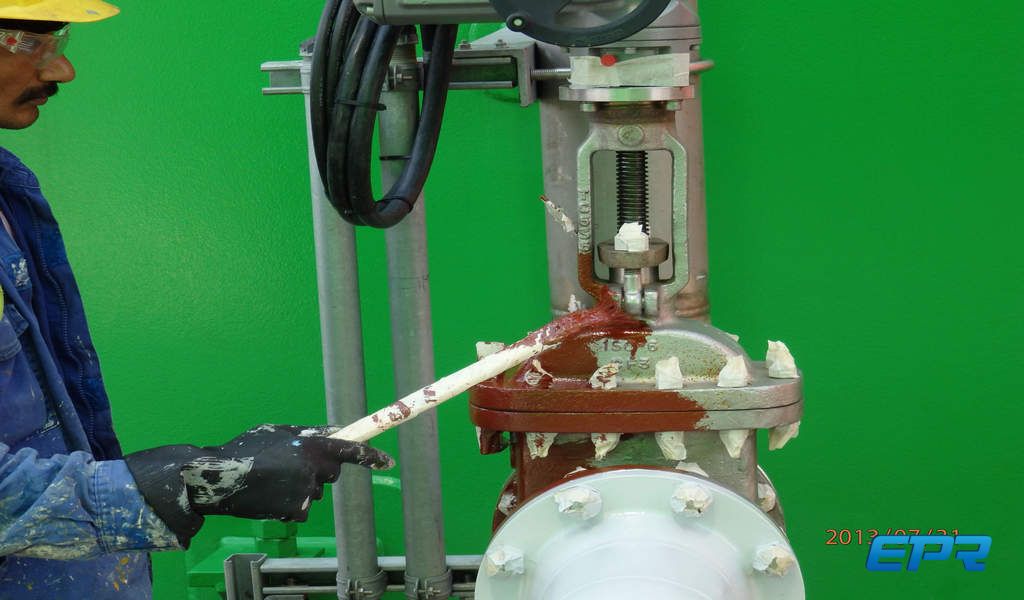

Coatings are typically shop applied and touched up in the field. On a large power station, there is considerable touch-up and it must be done correctly.

Briefly, as mentioned elsewhere in this Blog, coatings are not "paint", they are an engineered product that requires skilled personnel to apply properly. In this case there are three coats in the system. A zinc primer, epoxy mid-coat, followed by a urethane topcoat. Details... No coating will stick to steel substrate that is dirty, too smooth, or otherwise not prepared to the coating manufacturers requirements. An epoxy mid-coat sticks well to a zinc primer but does not stick to a urethane topcoat. If epoxy is left without a urethane topcoat, it deteriorates from UV. Urethane in most case needs to be applied over epoxy.

So, if a repair needs to be made, the existing paint needs to be taken off down to the primer, or mid-coat, depending on the damage. However, epoxy (mid-coat) cannot be "slapped on" as to overlap onto existing urethane. It will not stick. Also, coatings cannot be applied over corrosion or dirt; seems obvious... Also, most coatings are catalyzed with a hardener which must be in correct proportions or the coating will never harden. Same if water is mixed in the coating system.

With that background in mind, it is easy to get the sense that indeed coatings require some knowledge to place and repair correctly. In the attached, it's easy to see how the hundreds (really thousands) of repairs EPR checked in several plants, are at least 98% defective from the moment they are applied. Those repairs will have rust and be in full failure within six months.

See if you can spot the problems...

No savings.

Varies by plant, but to re-perform is significant. If unrepaired, O&M is constantly painting, or lets plant rust.