Failed Expansion Bellows

At a new plant with large-scale desalination operations a recurring failure was noted. Dozens, probably hundreds, of failures of 24” rubber expansion bellows occurred due to incorrect installation.

The summary conclusion in this case is that the contractor provided no training or oversight to piping personnel responsible for installing this engineered device.

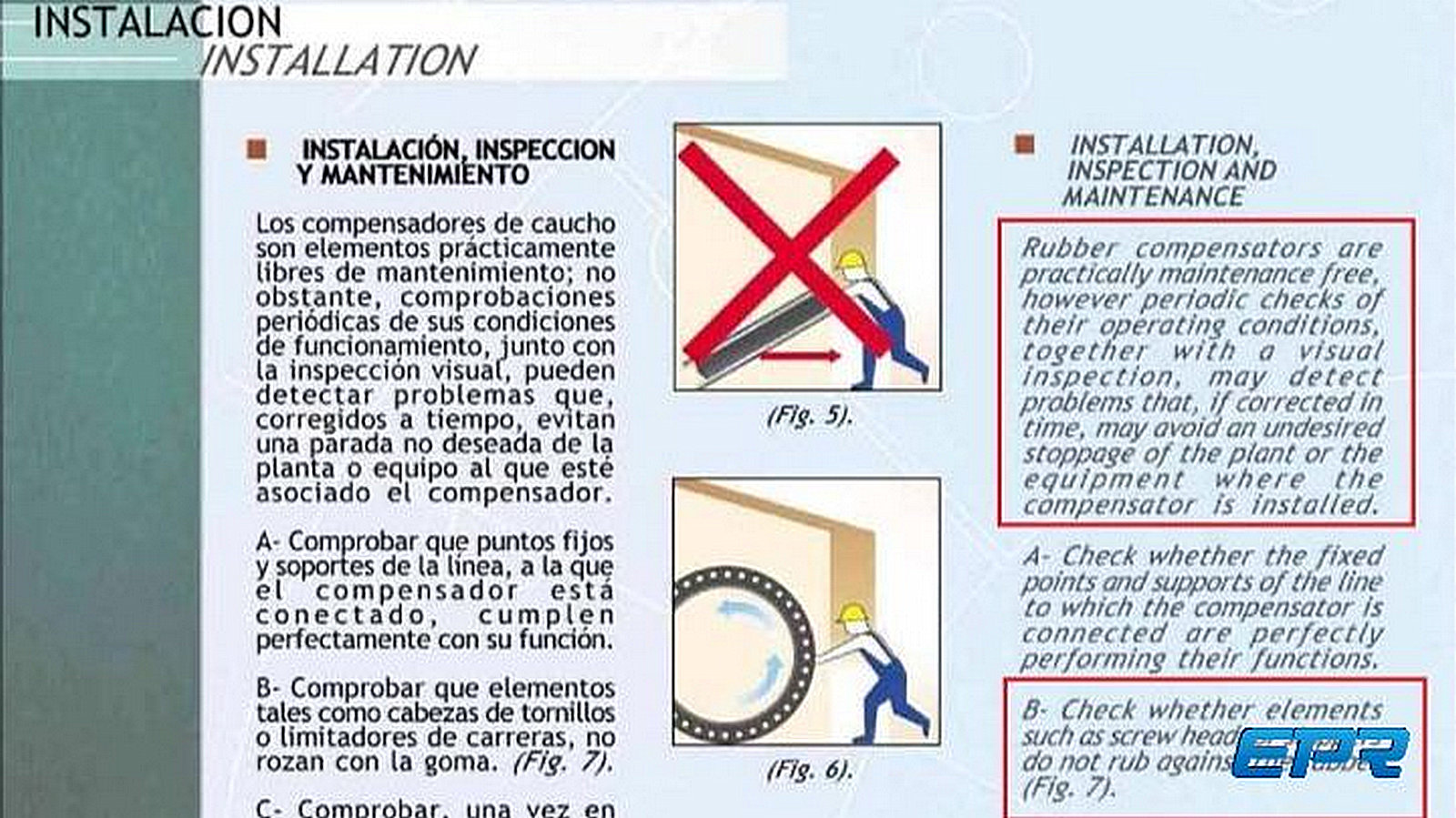

Operation of the systems created continuous piping vibration (normal levels) and the environment was quite hot, even the working fluid (seawater) was quite warm so the bellows was probably incrementally more relaxed. However, failure was certainly due to flange-to-flange dimension busts, misalignment of bolt holes, out of square flanges, and an assortment of creative abuse.

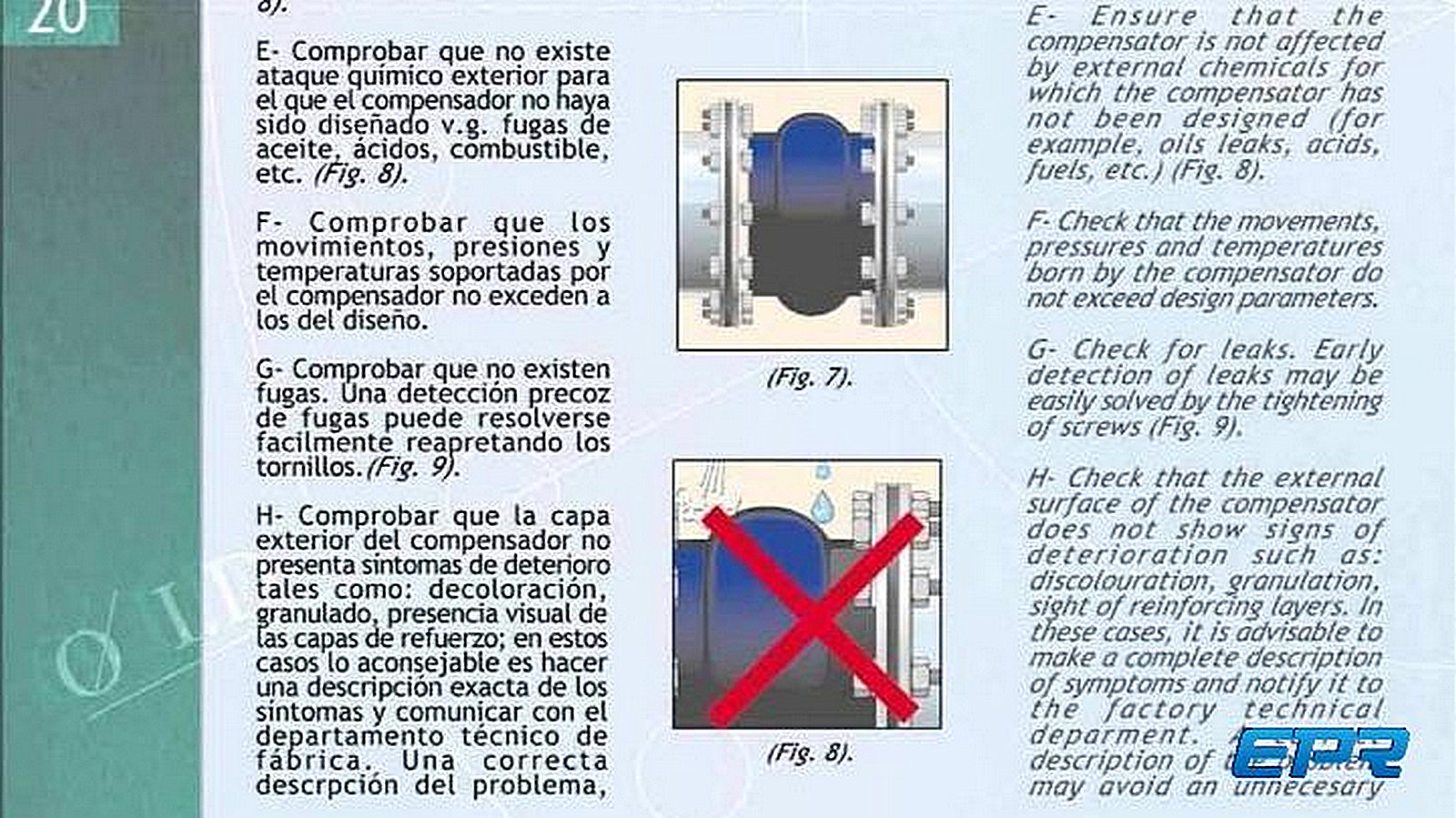

Where flange-to-flange distances were not to specification (narrow) the bellows nearly universally failed due to bolting impinging on the rubber outer layer of the bellows.

This defect could have easily been spotted by engaged contractor supervision, or by an owner’s representative, but neither addressed the problem which is easy to see. The OEM requirements provided with each bellows is easy to follow, so it is even more difficult to explain how the majority of these were installed incorrectly.

None.

Unknown. Device mortality will be a continual O&M cost for the life of the plant, unless piping changes are made during outages.