Porous Pump Castings

One aspect of power plant construction that seems to be a recurring issue is the ineffectiveness of shop inspection by some of the larger international inspection firms.

In this instance, stainless pumps were procured for seawater service. The usual shop inspection process was used, the reports sent and filed. No issues…

However, after a short period of service, there was a rash of pump failures. Keep in mind these pumps had been in service 18 months maximum.

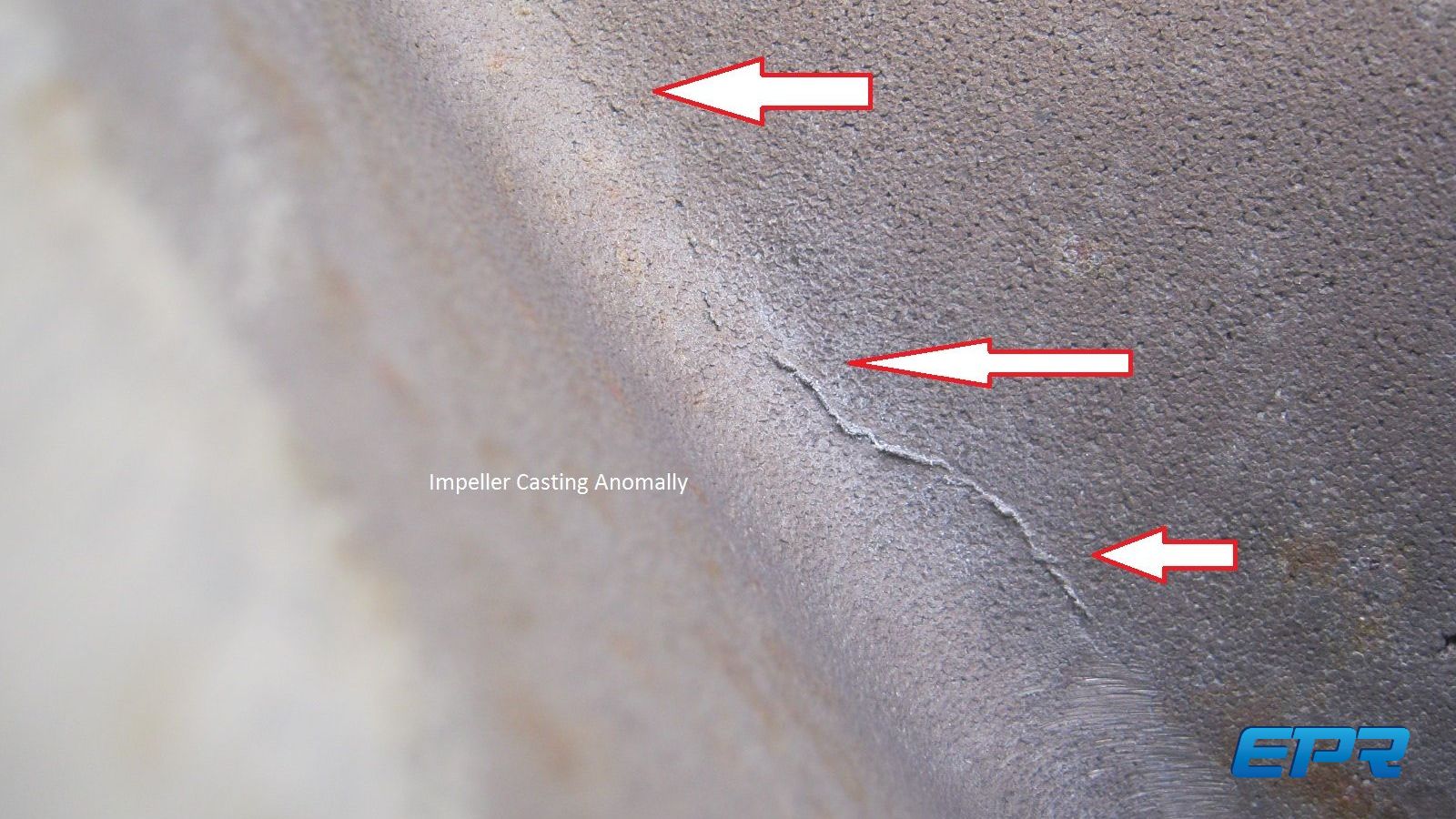

Upon closer look, many of the pumps had casting defects that should have been caught by the manufacturer, or perhaps the supplier of the equipment that included the pumps. If not then, certainly someone on site should have inspected them, but that didn’t happen either.

Once the pumps started to fail, it was easy to see it was a fatigue failure originating from flaws in the castings.

The pictures show several different units, including one that did fail resulting in a damaged pump casing.

Things like this do happen, but they happen less if an Owner actively reviews the inspector reports and questions the photograph details, perhaps requesting more data be sent that is not in the report if there is any doubt. When sourcing from parts of Asia, low cost inspectors often come from the same company-towns where the manufacturing is performed.

We all have stories, but let’s just suggest there can be certain conflicts-of-interest not readily knowable. In those cases, will an inspector provide a comprehensive clinical assessment of the work vs the performance requirements?

If inspection is important, it may be worth spending a bit more money to send someone associated with the owner's project team to represent the owner’s interest. It is also important to review carefully all inspections performed by an EPC contractor, even if an owner is not represented.

None. Should have forced supplier to deal with this issue at the factory.

None in this case because it was a Warranty item. However, these pumps are costly and from a foreign supplier. Dealing with this as an O&M group is not cheap or easy.