Piers, Sort of

Sometimes people ask us how new plants end up completing so badly. EPR is not typically engaged to develop a well-studied opinion about the details of execution failure, so we tend to stay away from speculation and focus on the task of Verification of Mechanical Completion. However, we can suggest with a high degree of confidence that plants that exit construction/commissioning in poor condition are almost never resulting from engineering failures. Yes, sometimes there are oversights and errors in the plans and specifications, but it is rare enough and usually minor enough to allow us to broadly conclude execution problems are at the site.

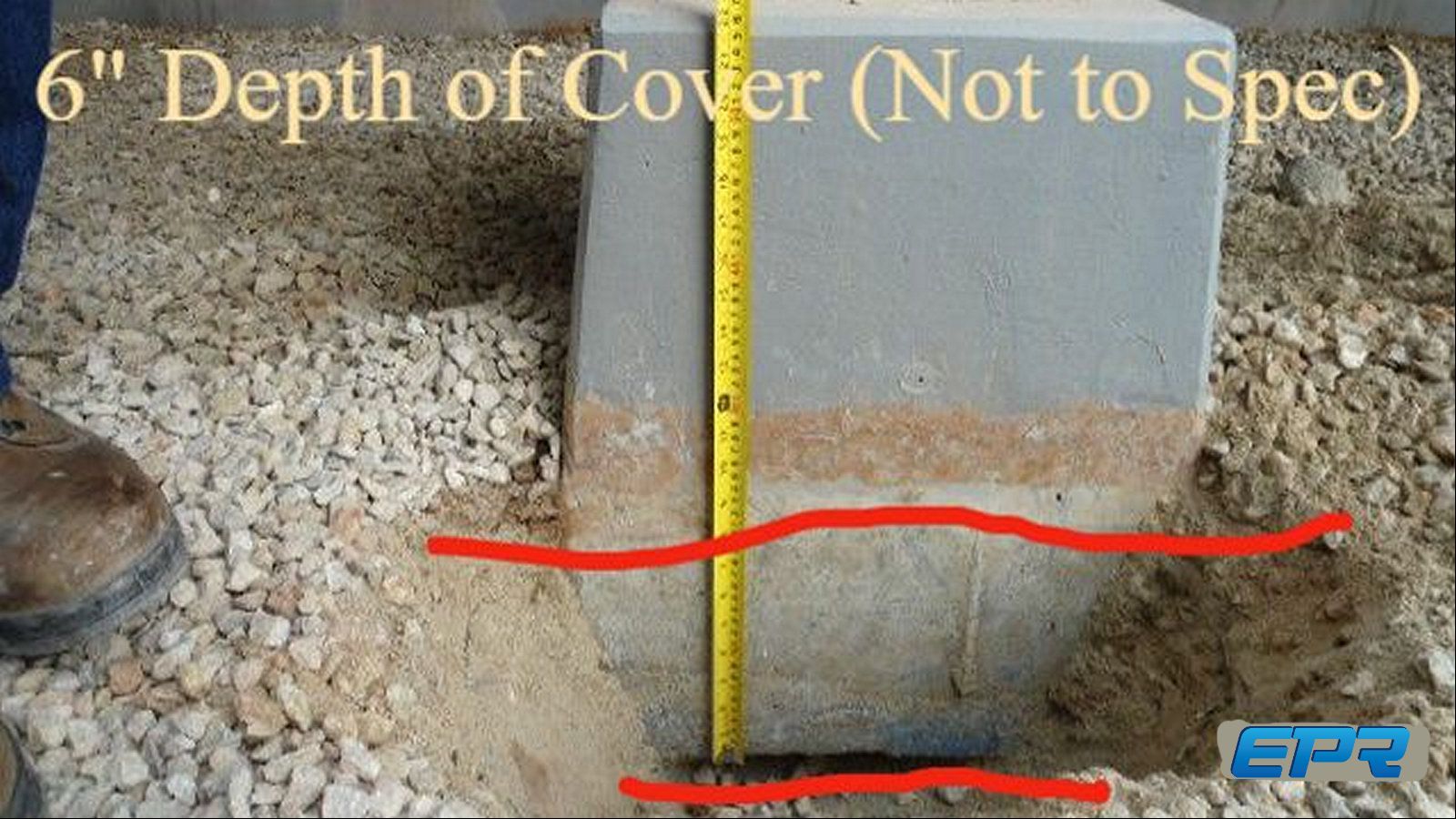

This is one example. The drawings indicated a pier design with a spread footing to effectively keep the pier in a fixed position when loaded from pipe stress. However, the site decided to precast piers with a greatly reduced footing area, which contravened the design.

This has resulted in about 300 piers that have settled and been pushed out of plumb by piping forces. Further, the depth of cover is not suitable (<250mm) compared with the original design (>400mm) and there is significant evidence of sub-grade settlement.

The result of this “short cut” is that most condensate and boiler feedwater piping around the HRSG’s is experiencing exceptional stress and is affecting pump alignment and a variety of other failure modes.

The photos in this posting do not illustrate very well the extensive nature of this defect and the substantial impact on plant operations.

Some, but relatively minor. ~$25,000.

The cost of replacement is small compared to the damage to rotating equipment and other components.