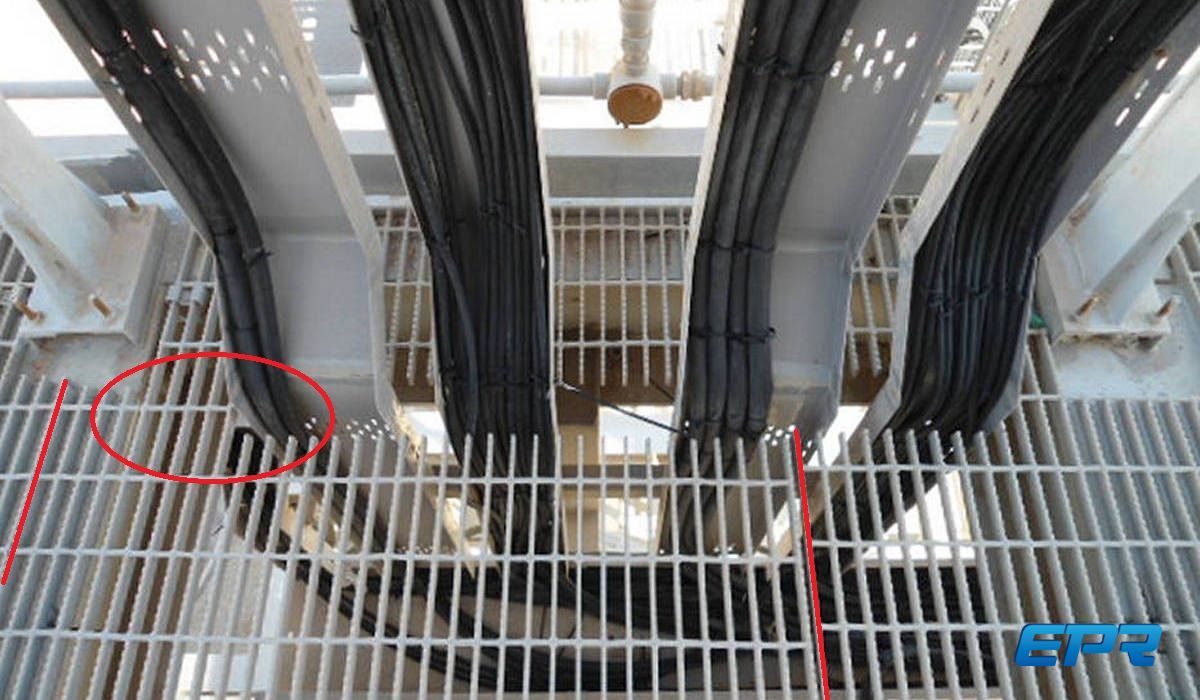

Not-So-Structural Grating

After noticing an unusual number of severe workmanship issues with grating penetrations, a study was conducted on one portion of a recently visited facility (one power block).

In the subject area, 231 penetrations through grating or deck plate did not conform to the requirements of contractor’s own Structural Erection Procedure, which states that all cuts of 3 grating bearing-bars shall be banded, and further, that field-cut openings shall clear insulation by 1”. The contractor’s own structural drawings also indicate a requirement/detail showing the penetrations of grating and checker plate reinforced with toe plate and banding.

Of the 231 inspections, 39 were missing banding, 174 had no toe plate, 10 did not meet the required insulation clearance, and 8 open holes were left in the grating. In total, roughly 100% of the penetrations were out of compliance with normal practice and the contractor’s criteria indicated above.

More concerning, is that the workmanship is so poor in some instances that almost none of the bearing-bars remain intact leaving the structural integrity of the deck in question. Given that these deck sections sometimes support more than one person and occasionally heavy items related to plant maintenance, this is a very serious finding.

If one of these grating sections “folded up”, a person could fall a great distance with the high probability of a fatality. Workmanship on grating must be taken seriously and the contractor should have a process that individually reviews each panel's installed condition.

Labor/Supervision savings and probably some material.

Contractor: Some material expense and labor. Scaffold in some locations perhaps. Owner: Risks injuring O&M personnel or worse.

Dangerous

Almost all the load bearing bars for this grating section have been cut. The toe plate on the left is not even welded sufficiently to add structural support and the left edge is not on the beam, both might have helped add support on the left side. Regardelsss this install is severely non-compliant and needed replacing before it collapses under an unsuspecting person.