Lightning Protection

On many projects, lightning protection is installed by a subcontractor and happens near the end of a project when other activities dominate everyone’s attention.

As a system, lightning protection requires attention to details, so it is not surprising that on projects that generally suffer from workmanship problems, the lightning protection installations also suffer. This is unfortunate, because the standards are in place to provide guidance for protection from strikes that can have severe consequences to plant equipment and personnel.

For those familiar with Houston, TX, it can be easy to understand the amount of lightning present is significant. The new plants used in these examples are also in a similar flash density (flashes/mi2/yr). This is to suggest, this is important.

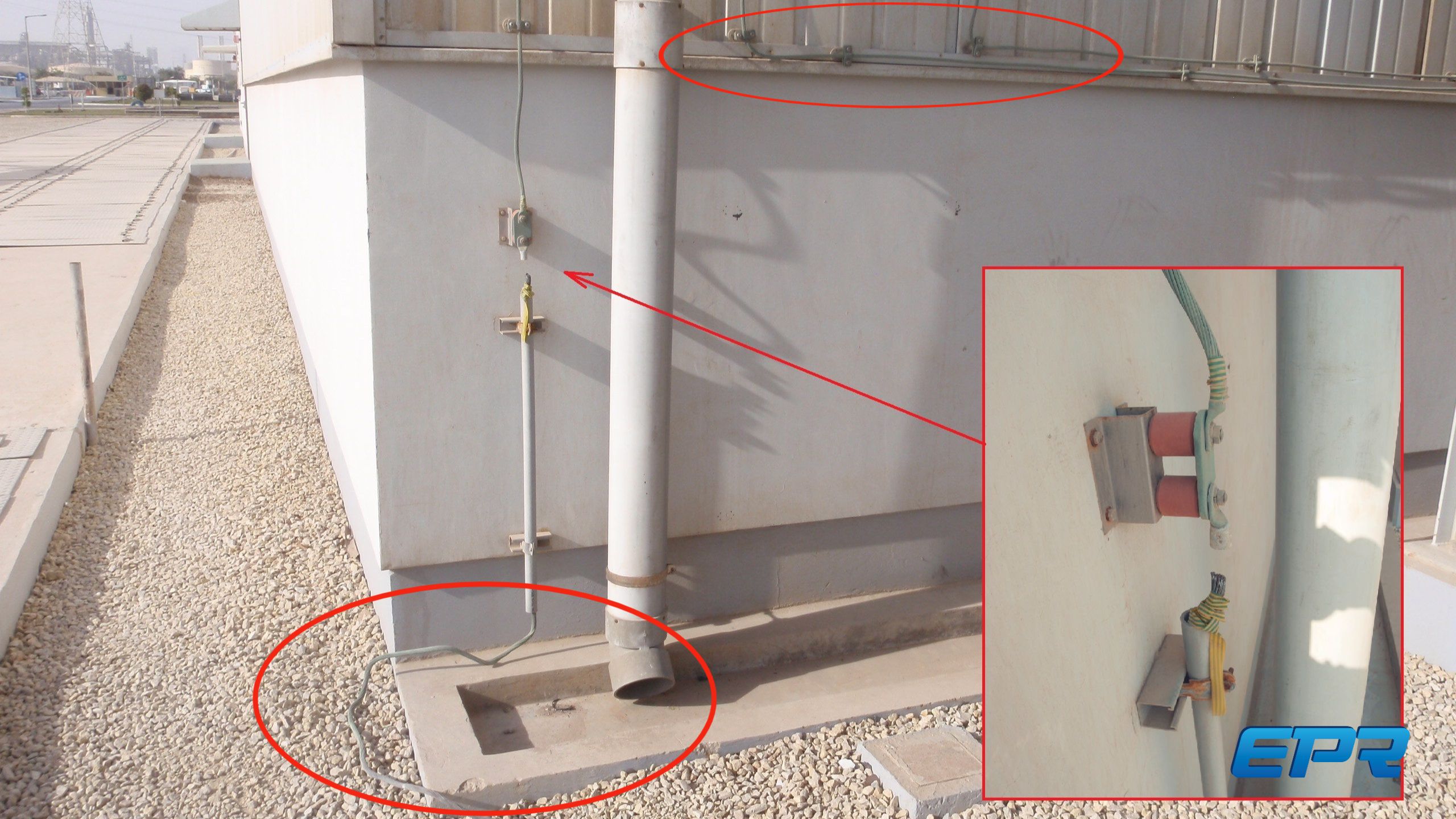

The EPC contract was clear in these cases regarding the requirements. The photos show workmanship defects that are representative of systematic failures throughout the systems. This included grounding conductor connections not being properly crimped and often disconnected, material incompatibility with building metals, missing building connections, unprotected zones, missing protection at building roof corners, U or V pockets in conductors, bends <90 degrees, bend radius <8”, conductor protection to 6’ above ground, missing bonding on masts, and an almost limitless variety of other creative defects.

The main thing to understand about lightning is that it travels directly from the strike point to ground. It will not follow a conductor that makes sharp bends or upward routing. There is typically so much energy that a lightning system with these types of issues will force the lightning to jump into the building or other close paths to ground. In other words, this vacates the protection the system is designed to provide.

Some examples of lightning strike impacts are fires, loss of lube oil to turbines and resulting damage, DCS system failure, personnel injury, and a variety of serious consequences.

For projects located in regions where there is a high lightning density, it is very important to audit these installations as part of commissioning and project completion to be certain the facility is protected.

None.

Repairing a bad installation is not largely expensive, however, significant cost can occur for an Owner if a lightning strike occurs without a functional protection system.