Electrical Zip(less) Ties

Recently EPR evaluated a facility, which among other difficulty, suffered from a condition that is unusual but serious in that essentially all the nylon cable (zip) ties were defective. While the zip tie is a wonderful time saving and usually effective component widely used to affix electrical cables, it must remain unaffected by its environment to remain durable over time.

In this instance, the plant was less than two years old and located in a high UV zone. This defect was so severe that gently touching the installed tie would cause a brittle failure. The plant was littered with failed zip ties that had fallen from tray systems and cable installations.

One supplier used by the contractor indicated in the technical literature that the ties are compliant with NEC, meaning Nylon, UV, weather, seawater, and oil resistant type from Panduit /T&B or equivalent. However, those ties have failed almost universally. While some cursory research was performed on the ties, it is not clear exactly why the ties were brittle and failing, but they certainly all needed replacing. The real suspicion is that all the ties were possibly from a counterfeit manufacturer and the material (nylon?) was not rated for UV contrary to the claims made.

Unfortunately, there are perhaps millions of these defective zip ties in the subject plant, so the labor to replace all of them is significant. Left unresolved, over time the installation becomes non-compliant with NEC code requirements because the cables are no longer affixed at the required intervals.

When this happens en mass, the plant can eventually experience spurious operational events (cable strain) and does not restrain fault current reaction forces in a manner intended by the designer/code.

Negligible material savings.

Contractor: Somewhat time consuming, especially in an operational plant. Owner: Outage events and unpredicatablity are hard to quantify, but even a single lost generation day is expensive.

In the Wind

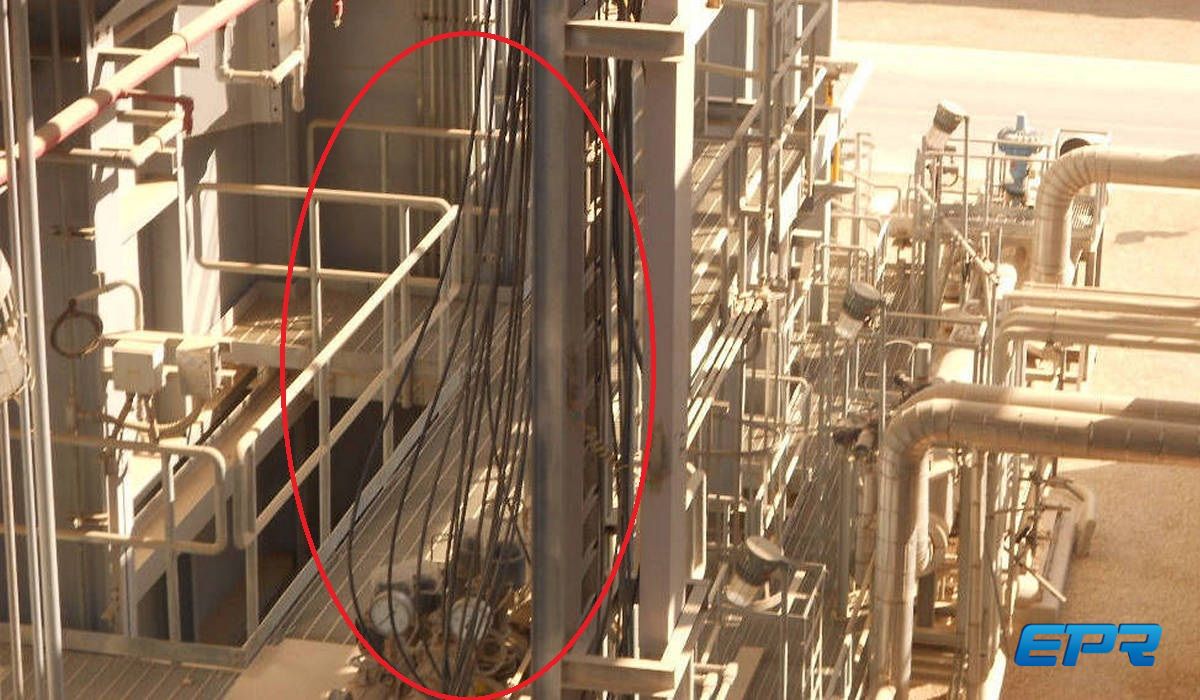

Notice the cables have fallen out of the vertical cable tray in the center of the photo. It's not hard to envision a problem developing as those cables hang unsupported. Cable tray systems are no longer "systems" when they appear in this condition.