Dirt... and Fuel Gas

As background, one critical system in a power plant is fuel gas. Typically, every system is cleaned to a condition that is nearly spotless. This is especially true of fuel gas because it feeds the turbines and duct burners. EPR evaluated a plant that was physically very large. The fuel gas header was 1.5+ miles long, inside the plant downstream of the supplier custody-filters. The system changed elevations, had countless fittings, and pipe size changes. Clearly, this is a difficult system configuration to clean well for an inexperienced crew.

Prior to EPR being involved, roughly 50 warranty claims were raised against the EPC contractor that enumerated roughly 300+ failures of valves, flame scanners, regulators, and really anything in the system with a seat or rubber O-ring. The EPC contractor refused to address the issue on-the-whole with a proper RCA (root-cause analysis), instead dealing with each item as if unrelated.

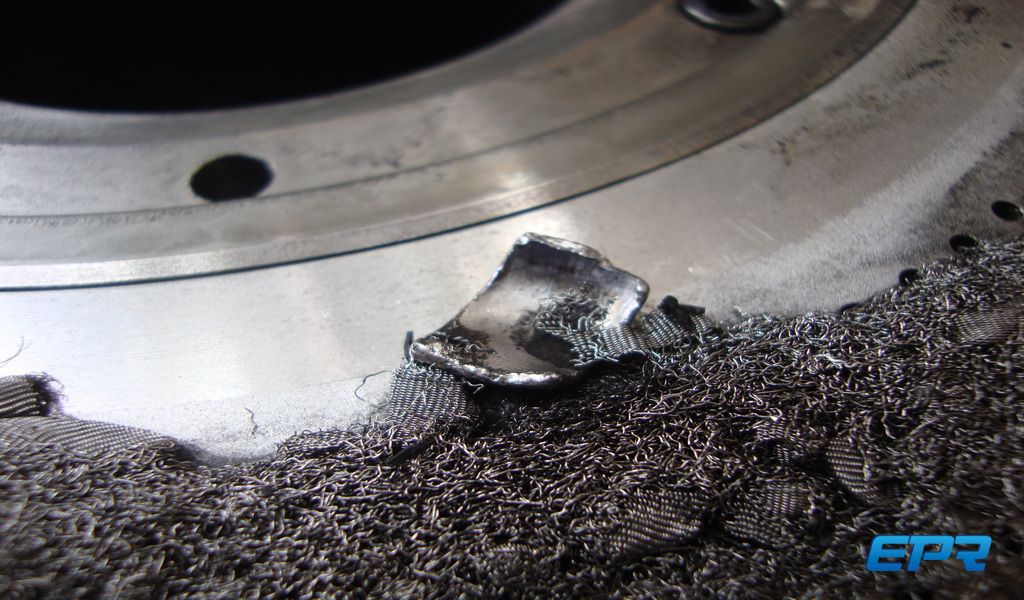

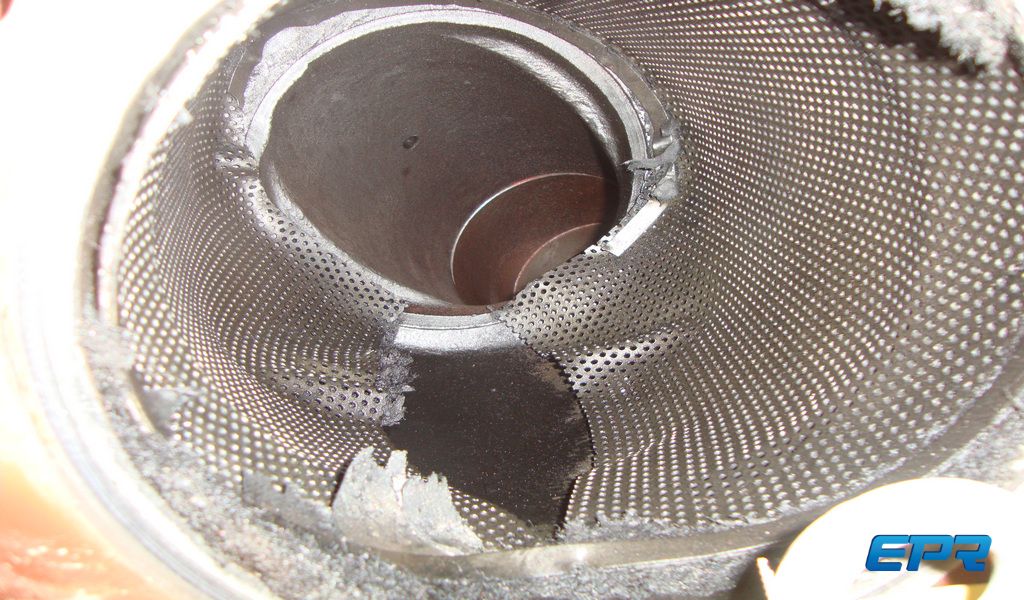

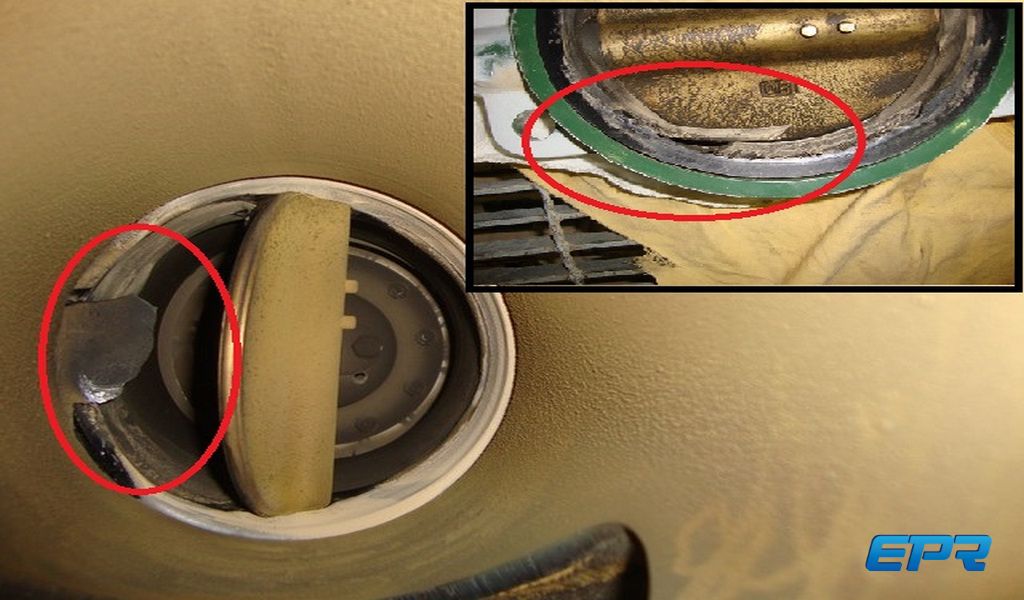

The attached photographs tell the story. This system is so full of dirt and contamination that it's not defensible to indicate proper, or perhaps any, commissioning occurred. Further, the duct burner strainer screens were collapsed during installation and completely useless, and a big part of the reason debris ended up at the burner skids. Perhaps even adding to the debris in the system.

The gas turbine filters were likewise full of debris, dirt, steel filings, scale, mud, and in a condition, that defies accurate written explanation.

With complex systems which may not clean well, or where minimum cleaning ratios cannot be achieved, the commissioning team should have confirmed by borescope and other visual inspection that the system was clean. As a side note, the filters at the plant demarcation were also evaluated and shown to be free of damage and had an expected level of dirt.

The consequence of such a condition can really be fully known, however, this plant had countless issues with duct burners and simply couldn't keep them running due to so much damage to components. Over time, the infant mortality conditions became less severe as filters were changed, removing dirt, etc...

No Savings. Contractor went through "motions" of cleaning system, just didn't!

Just in terms of Owner down-time for needless repairs this is millions of $'s. Parts, labor, etc...